Inquiry

Form loading...

When navigating the world of boating, understanding marine fasteners is crucial. These small yet significant components are vital for every maritime project. From securing deck hardware to fastening rigging, quality marine fasteners directly influence safety and performance on the water.

Choosing the right marine fasteners can be daunting. There are different types, materials, and sizes to consider. Stainless steel and corrosion-resistant options are often favored. However, mistakes are common. For example, using inappropriate fasteners can lead to failures. It is essential to evaluate your needs thoughtfully.

In this guide, we will explore 2026's top marine fasteners. The focus will be on quality, durability, and suitability for your specific applications. Attention to detail is paramount in ensuring reliability and longevity at sea. Be prepared to reflect on your fastener choices for better outcomes.

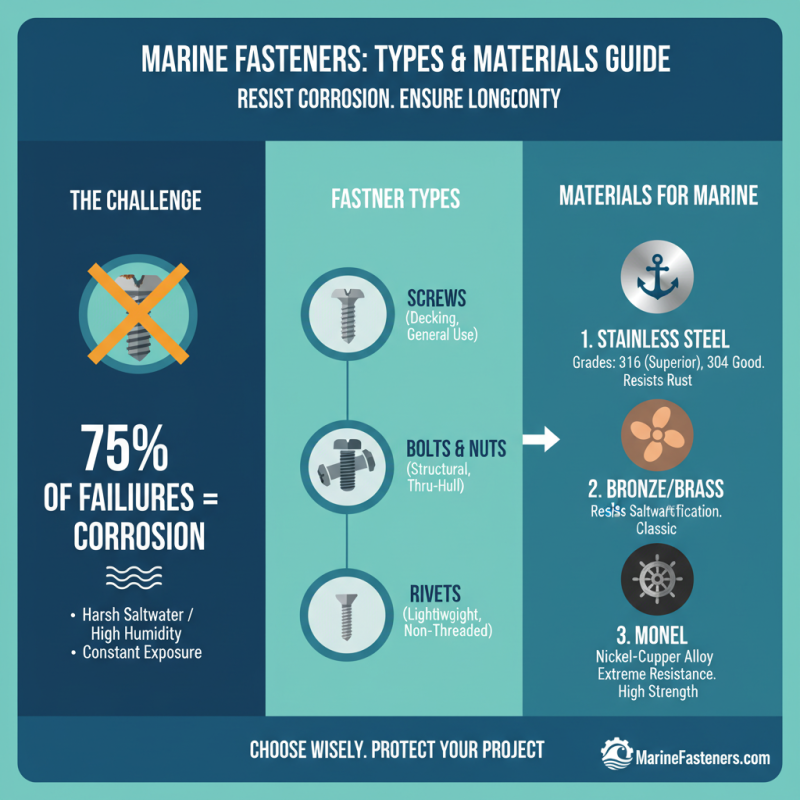

When it comes to marine fasteners, understanding types and materials is crucial for any project. Marine environments demand components that resist corrosion and wear. According to a recent industry report, around 75% of fastener failures in marine applications stem from corrosion-related issues. Selecting the right material is vital for longevity.

Stainless steel is a popular choice, favored for its strength and resistance to rust. However, not all stainless steel is equal. Type 316 stainless steel offers superior corrosion resistance due to its molybdenum content. Yet, it’s important to note that even this material can corrode under certain conditions, such as exposure to harsh environments or inadequate maintenance.

Other materials include nylon and brass, each with unique advantages. Nylon fasteners offer lightweight options but may not withstand high stress. Brass provides good durability but lacks the corrosion resistance of stainless steel. As you choose fasteners, remember that each option has limits. It's essential to assess the specific demands of your environment. Keeping these factors in mind will help avoid unexpected failures.

Choosing the right marine fasteners is crucial for ensuring optimal performance in maritime environments. These fasteners must withstand harsh conditions, including saltwater, moisture, and varying temperatures. Corrosion resistance is one of their key features. Marine-grade materials, such as stainless steel or titanium, are typically recommended for this purpose.

According to industry reports, about 70% of fastener failures in marine applications are due to corrosion. It’s essential to understand what materials offer the best protection. Coatings, such as epoxy or galvanized finishes, add another layer of defense. However, not all coatings are created equal. Choose coatings that match your specific marine environment for best results.

Tip: Always consider the environment. For coastal areas, prioritize materials with high corrosion resistance. In freshwater settings, traditional fasteners may suffice. Remember, the right choice can prevent costly repairs and ensure safety.

Another important feature is tensile strength. Fasteners should be capable of holding heavy loads without breaking. Some materials might meet the strength requirements but fail in other aspects like flexibility or weight. The balance between these factors often leads to trial and error in selecting the best fasteners. Be prepared for some back-and-forth in your decisions. Research and testing are invaluable here.

Tip: Consult industry reports and user experiences. Understanding past failures can guide better choices. Ultimately, a thoughtful approach is vital for achieving high performance in marine applications.

Choosing the right marine fasteners for your application is critical. The marine environment is harsh. Corrosion resistance is paramount. According to a report by the National Marine Manufacturers Association, 50% of marine-related failures stem from inadequate fastener selection. This statistic underscores the need for careful consideration when choosing materials.

Consider the types of materials available. Stainless steel is common but may not always be suitable. Certain grades of stainless steel resist corrosion better than others. Marine-grade fasteners made from bronze or nylon might be ideal in specific environments. A recent study indicated that nylon fasteners provide lightweight solutions in non-load-bearing applications, proving effective against chemical exposure.

It’s vital to examine the specification of your project. Fasteners should match the load requirements and potential stress factors. An often-overlooked detail is the torque specifications. Over-tightening can lead to thread stripping or breakage. An appropriate fastener should account for service conditions including temperature fluctuations and moisture levels, which can affect performance. Engaging in proper research and testing phases can mitigate costly errors in the long run.

Marine fasteners play a crucial role in ensuring the integrity of maritime structures and vessels. To prolong their lifespan, regular maintenance is essential. Start by inspecting the fasteners for signs of corrosion or rust. This is especially important for those exposed to saltwater. Paying attention to these early signs can save time and costs.

Cleaning is vital. Use a soft brush and fresh water to remove debris. For tough spots, a mild detergent works wonders. Avoid harsh chemicals. They can damage the metal surface. After cleaning, apply a silicone-based lubricant to protect against moisture. This gentle layer provides a shield against the elements.

Consider the installation process. Over-tightening can lead to stress fractures. Ensure that you use the recommended torque settings. Periodically, check the tightness of fasteners. Loose ones can cause leaks or structural damages over time. Taking these steps helps maintain safety and reliability in marine operations.

In recent years, marine fastener technology has witnessed significant advancements. Innovations focus on enhancing durability and corrosion resistance. Traditional materials often fail in harsh marine environments. So, companies are now exploring composites and specialized coatings. These alternatives promise longer-lasting performance.

Smart fasteners are becoming a trend. They feature sensors that monitor structural health. This technology can detect stress and corrosion in real-time. However, integrating these systems into existing vessels poses challenges. Compatibility issues could arise, leading to higher costs.

Sustainability is another crucial area. Many manufacturers seek eco-friendly materials. While this is commendable, questions remain about their long-term performance. Some options may not hold up under extreme conditions. This uncertainty requires careful consideration. The marine industry must balance innovation with reliability.