Inquiry

Form loading...

In today's fast-paced infrastructure landscape, selecting the right Pole Line Hardware is crucial for optimizing project efficiency and ensuring longevity in utility installations. According to a recent report by International Energy Agency (IEA), the global demand for electricity is anticipated to increase by 30% by 2040, necessitating the need for robust and reliable pole line systems. Furthermore, a study by the Electric Power Research Institute (EPRI) indicates that the proper selection of pole line components can enhance safety and reduce maintenance costs by up to 25%. By investing in high-quality Pole Line Hardware, project managers can not only meet the growing demand for energy infrastructure but also ensure a sustainable and efficient operational framework. This guide will explore the myriad benefits of choosing the best hardware for pole line installations, helping you unlock greater efficiency and reliability for your projects.

In today's fast-paced construction industry, selecting high-quality pole line hardware can significantly enhance project efficiency and overall execution. Recent studies indicate that using superior materials can lead to a 20-30% reduction in maintenance costs, which is crucial for long-term project sustainability. Reliable pole line hardware ensures the integrity of electrical systems and minimizes downtime, allowing teams to focus on project milestones without unforeseen interruptions.

Moreover, advancements in technology, such as cloud computing and AI integration in project management, are further propelling the construction sector towards greater efficiency. By harnessing these technologies, construction businesses can optimize resource allocation and track progress in real-time. Data shows that companies implementing cloud-based solutions see a 40% improvement in collaboration and data accessibility, streamlining operations significantly. High-quality pole line hardware, paired with innovative technological solutions, creates a robust foundation for successful and efficient project execution in the competitive construction landscape.

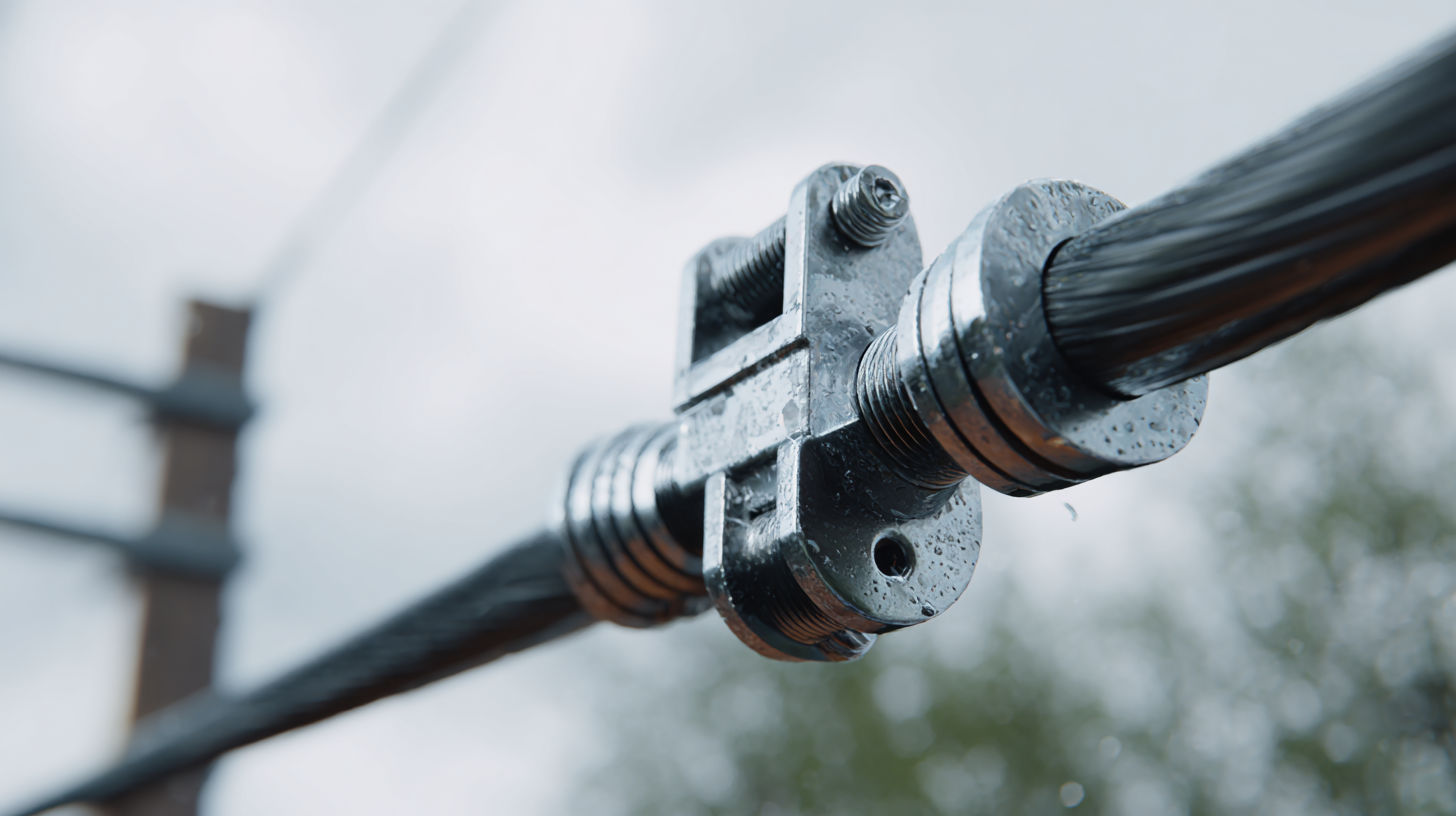

When choosing pole line hardware for your projects, recognizing key features is essential for maximizing efficiency. High-quality pole line equipment should prioritize durability, ensuring that materials can withstand environmental stresses such as wind, rain, and temperature fluctuations. Look for hardware made from corrosion-resistant materials to enhance longevity, especially in harsh climates.

Another critical feature is ease of installation. Opting for pole line hardware that allows for straightforward assembly can significantly reduce project downtime. Incorporating modular designs can also provide flexibility for various setups, making it easier to adapt your hardware to different project requirements.

Additionally, consider the importance of compatibility with existing infrastructure. The best pole line equipment should integrate seamlessly with current systems, promoting a streamlined workflow. Investing in reliable equipment not only boosts productivity but also minimizes the risks of future failures and maintenance issues.

Choosing the right pole line hardware is a crucial investment for any project, particularly when considering long-term cost implications. Premium hardware not only enhances operational efficiency but also significantly reduces maintenance and replacement costs over time. According to industry reports, companies that opt for high-quality materials can see a decrease in lifecycle costs by up to 30%, making the initial expense worthwhile. In this landscape, the importance of durability and reliability cannot be overstated—quality hardware minimizes downtime, which is vital for maintaining productivity.

**Tip:** To ensure you are selecting the best hardware, consider conducting a total cost of ownership analysis. This involves assessing not just the purchase price, but also installation, maintenance, and potential replacement costs over the hardware's lifespan.

Moreover, investing in premium hardware aligns with the growing trend of sustainability in construction and utility projects. It can lead to lower energy consumption and reduce the carbon footprint associated with frequent repairs or replacements. A study from the construction sector indicates that businesses committed to sustainability practices, including quality material investments, report substantial savings in overall project costs.

**Tip:** Always check for certifications or performance standards when choosing hardware; this guarantees compliance with industry best practices and lends credence to claims of reliability and efficiency.

Advanced manufacturing techniques play a crucial role in elevating the performance of pole line hardware, driving efficiency and reliability in electrical infrastructure projects. Recent studies indicate that the integration of precision engineering and innovative materials can enhance the durability and operational efficiency of pole line components. For instance, a comprehensive analysis revealed that upgraded designs could reduce energy losses by as much as 10%, contributing to overall cost savings in power distribution systems.

Furthermore, the implementation of advanced manufacturing technologies, such as 3D printing and robotic assembly, allows for greater customization and faster production times. According to industry reports, these methods not only decrease lead times but also lead to higher quality outputs, which are critical in ensuring the longevity of pole line hardware. In applications where equipment needs to withstand diverse environmental conditions, such enhanced performance is particularly vital. By investing in advanced manufacturing solutions, companies can secure a competitive edge through improved product reliability and efficiency.

The global market for pole line hardware is currently experiencing significant shifts, driven by advancements in technology and increasing demand for sustainable infrastructure. Manufacturers are adopting innovative materials and designs that not only enhance the durability and efficiency of their products but also reduce the carbon footprint of their operations. Trends such as the integration of smart technologies into pole line hardware are gaining traction, allowing for better monitoring and maintenance, ultimately leading to longer service life and minimized downtime.

Additionally, as countries invest heavily in upgrading their energy grids and communication networks to support renewable energy sources, the need for high-quality pole line hardware has become more pronounced. This presents a unique opportunity for stakeholders in the industry to capitalize on the increasing demand by offering products that meet the rigorous standards required for modern applications. The growing importance of reliability and safety in hardware selection is a clear reflection of the evolving global market, prompting project managers to prioritize the best options available in order to ensure the success of their initiatives.

| Dimension | Description | Impact Level | Market Trend (%) |

|---|---|---|---|

| Material Quality | Durable and weather-resistant materials reduce maintenance costs. | High | 10% |

| Installation Time | Quick installation techniques lead to reduced labor costs. | Medium | 15% |

| Weight Efficiency | Lightweight designs ease transportation and handling. | Medium | 12% |

| Environmental Impact | Sustainable materials minimize environmental footprint. | High | 8% |

| Innovative Designs | Adaptive designs improve functionality and user experience. | High | 20% |