Inquiry

Form loading...

Nut Prestressed Anchorage plays a critical role in various engineering projects. This technology enhances structural integrity, ensuring safety and durability. It is essential for applications in bridges, buildings, and retaining walls. Choosing the right solutions can be challenging, yet it is vital for successful outcomes.

Different projects require specific types of Nut Prestressed Anchorage. Each solution has its strengths and weaknesses. Some may excel in high-stress areas, while others suit lighter loads. Understanding these nuances is crucial for making informed decisions. Mistakes in selection could lead to structural failures.

Project managers must weigh factors such as cost, installation, and performance. Every project is unique; thus, a one-size-fits-all approach is rarely effective. Solutions should be tailored to meet specific needs. Reflecting on past experiences can guide better choices in the future. Always seek innovation and improvement in your anchorage strategies.

Nut prestressed anchorage plays a crucial role in construction projects. This method aids in securing structural elements, providing stability and strength. With the right anchorage solution, projects can resist various loads and environmental conditions effectively.

Understanding the basics is essential. Nut prestressed anchorage consists of nuts and bolts that work together. The nuts create tension, securing the system in place. This method can prevent failures during construction stress tests. However, not all designs work equally well. Some may require adjustments for specific conditions. It’s important to analyze each project’s unique needs.

The benefits are significant. Enhanced durability and reliability are prime advantages. When designed correctly, these systems can extend the lifespan of structures. However, improper installation can lead to issues. Regular inspections and maintenance are critical. Attention to detail can make or break the integrity of the project.

Nut prestressed anchorage systems are vital in modern construction. They enhance structural integrity and durability in various projects. Understanding key types can help you make informed choices.

One popular option is the wedge-type nut anchorage. This design provides reliable performance during tensioning. It's suitable for multiple applications, from bridges to high-rise buildings. However, installation can be complex, requiring skilled labor. Mistakes here can lead to failures. Always assess the experience of your team.

Another option is the bonded nut anchorage system. This type uses epoxy to secure the nuts, creating a strong bond. It's particularly effective in areas with high stress. Yet, it demands precise application to avoid weak spots. Proper curing time is essential to achieve maximum strength. Rushing this process can result in significant issues later. Always test the installation site before full deployment.

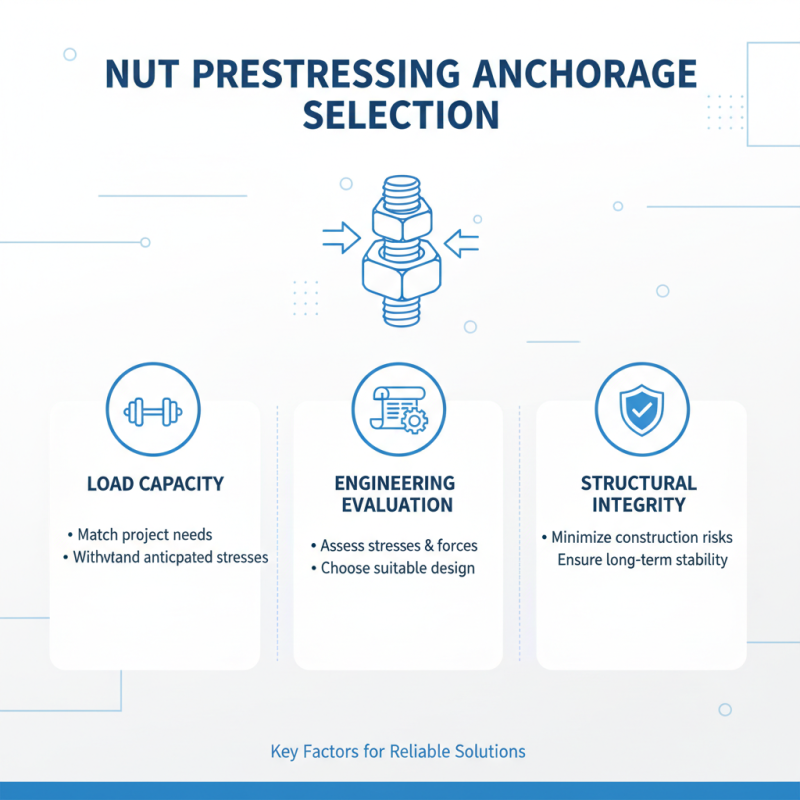

When selecting anchorage solutions for nut prestressing, several key factors come into play. The load capacity of the anchorage must align with the project requirements. Engineers should evaluate the anticipated stresses and choose a design that can withstand them. This consideration minimizes risks during construction and ensures structural integrity.

Material compatibility is crucial. Selecting materials that resist corrosion will extend the life of the anchorage. The environmental conditions of the site significantly influence this choice. For instance, a coastal environment may require specialized coatings. Ignoring these details can lead to premature failure and costly repairs.

Installation techniques also matter. The precision during installation affects long-term performance. Misalignment can compromise the anchorage's effectiveness. Regular training for the crew is essential to mitigate mistakes. Reflecting on past projects can provide valuable insights for improvement. Balancing all these elements often requires careful planning and, at times, a willingness to adapt designs based on evolving needs and feedback.

When it comes to nut prestressed anchorage, installation techniques play a crucial role. Proper installation ensures the durability and reliability of the anchorage systems. One common technique involves the careful alignment of the nuts and anchors. Misalignment can lead to uneven load distribution. This often requires precision tools and skilled personnel, which might not always be available.

Using the right torque is another important aspect. Over-tightening can damage components, while under-tightening can compromise the structural integrity. It’s essential to follow guidelines closely. However, not all projects have identical needs. Adjustments may be necessary based on specific site conditions. This can lead to trial and error processes, frustrating some teams.

Training and experience significantly influence installation success. Inexperienced workers might overlook small but critical details. Regular checks and balances during installation can mitigate this risk. Reflecting on past projects often reveals areas for improvement. Learning from mistakes is vital for future installations. Ultimately, a detailed approach towards nut prestressed anchorage can lead to better outcomes.

This chart displays the effectiveness ratings of various nut prestressed anchorage solutions based on project requirements, helping you identify the best options for your construction projects.

Nut prestressed anchorage solutions have gained traction in various construction projects. These systems provide robust support and enhance stability. They are often used in bridges, tunnels, and high-rise buildings. With their ability to handle high tension loads, they ensure safety and durability. Engineers value their flexibility in application. The design can adapt to different structural requirements.

In practice, case studies reveal some challenges. In one project, a bridge experienced unexpected movement. The anchorage system needed adjustments to handle dynamic loads effectively. This incident prompted a thorough review of the initial design. Another case involved a tunnel where the anchorage didn’t perform as envisioned. Due to unforeseen soil conditions, additional reinforcements were necessary. These experiences highlight the need for meticulous planning. They also remind us to stay vigilant during construction.

Common applications also include retaining walls. These walls often bear heavy lateral pressures. Nut prestressed anchorage can enhance their performance significantly. However, the installation process must be precise. Even minor errors can lead to serious issues. Understanding the specific conditions of each project is crucial. Each case provides lessons that push innovative solutions forward.