Inquiry

Form loading...

Selecting the right Mushroom Head Bolts for your project is crucial. These fasteners are designed for a variety of applications. According to a 2022 report by the Fastener Quality Act Association, the demand for specialized fastening solutions is increasing at an annual rate of 5%. This growth highlights the importance of careful selection.

Expert and industry leader, John D. Smith, states, “Choosing the right fasteners can make or break a project.” His insights emphasize the need to understand the specifications of Mushroom Head Bolts. Factors like material, size, and load capacity matter significantly. Each component impacts structural integrity and performance.

Choosing incorrectly can lead to failures. A wrong size can compromise strength. Likewise, material choices affect corrosion resistance. These mistakes often go unnoticed during planning. By considering these details, you ensure a reliable outcome. The right Mushroom Head Bolts not only enhance durability but also facilitate efficient assembly. Investing time in the selection process pays dividends in the long run.

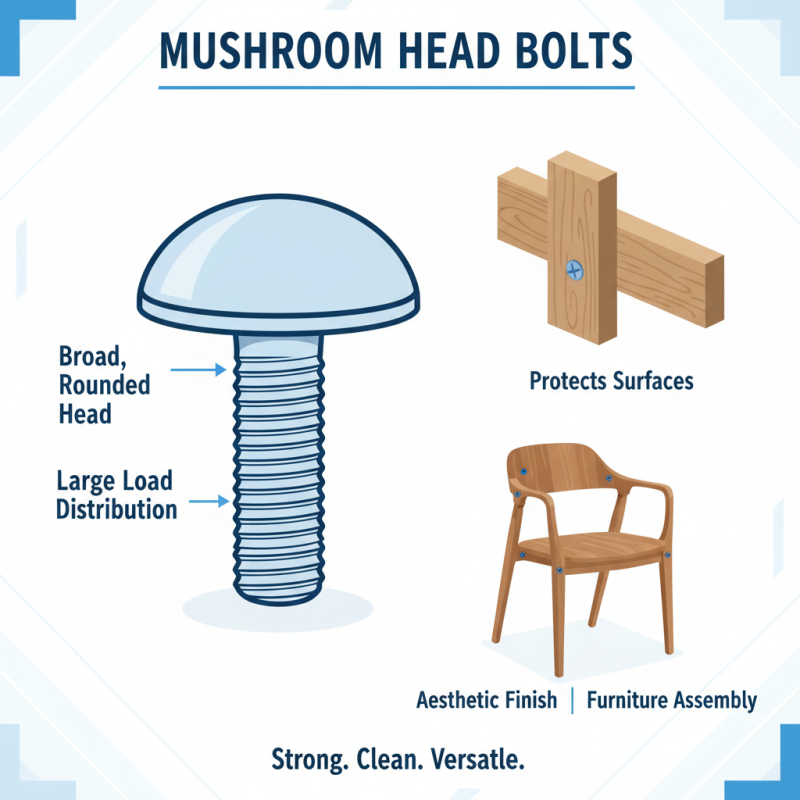

Mushroom head bolts are unique fasteners defined by their broad, rounded heads. These bolts are often used in applications where a larger surface area is needed for load distribution. Their design makes them ideal for securing materials without damaging the surface. They can be especially beneficial in aesthetic projects, such as furniture assembly, as they can provide a clean, finished look.

When selecting mushroom head bolts, consider the material. Stainless steel is resistant to corrosion and is suitable for outdoor projects. On the other hand, carbon steel offers strength for heavy-duty tasks. Remember that the head diameter can affect performance. A larger head distributes stress better but may not fit in tight spaces.

**Tip:** Always match the bolt size to your project requirements to avoid issues. Using the wrong size can lead to weak joints.

Another important aspect is thread count. A higher thread count offers more grip, ensuring stability. However, if the threads are too fine, they may strip easily under pressure.

**Tip:** Test a few bolts before making a large purchase. It can save you from unexpected surprises later on. Choose wisely, as the right bolt can enhance both functionality and appearance.

When choosing mushroom head bolts, material types play a crucial role. Stainless steel is popular due to its corrosion resistance. It works well in outdoor projects and humid environments. However, it can be more expensive than other options. Consider if the investment is justified for your project.

On the other hand, carbon steel is a cost-effective choice. It is sturdy and reliable for many applications. However, it lacks protection against rust and corrosion. That could lead to issues in damp environments. Always think about the longevity of your project before deciding.

Plastic mushroom head bolts are lightweight and resistant to certain chemicals. They are suitable for specific applications like electronics. Yet, they may not provide the same strength as metal options. Each material has its trade-offs. Reflecting on your needs will guide you to the right choice.

When selecting mushroom head bolts, size and length are critical. They must fit your project precisely. The right size can influence the overall integrity of your assembly. According to recent industry reports, about 30% of equipment failures are attributed to improper fastener sizing. This emphasizes the need for careful selection.

Consider the material you are working with. For softer materials, a shorter bolt may suffice. Yet, in more demanding applications, a longer bolt could be necessary. Studies indicate that nearly 25% of projects failed because the length of the bolt was misjudged. That can lead to unwanted stress and potential failure points.

Precision is key. Use calipers to measure accurately. Sometimes, a bolt might seem the right fit but, in reality, it can be the wrong length. Remember, a mushroom head can offer a larger bearing surface but might complicate fitting in tight spaces. It's a balancing act. Evaluating the environment where the bolts will be used also matters. Different conditions may require adjustments to your initial choice.

This bar chart represents the availability of various sizes and lengths of mushroom head bolts necessary for projects. The data showcases the quantity available for each size, helping you make an informed decision based on your project's requirements.

Choosing the right mushroom head bolts requires careful consideration of load requirements and strength metrics. Load requirements are critical to ensure the safety and efficiency of any project. A study by the American Institute of Steel Construction indicates that proper load calculations can prevent structural failures. Underestimating these loads can lead to catastrophic failures.

Mushroom head bolts have unique strength characteristics. They often exhibit high shear strength, which is vital for applications where forces act in sideways directions. According to data from the Fastener Quality Act, these bolts can withstand significant load variations. However, not every project benefits from their use; sometimes, standard bolts may meet required strength metrics more effectively.

Engineers must analyze their specific needs closely. Overlooking load diversity can compromise structural integrity. Factors, like environmental conditions or dynamic loads, influence bolt performance. You may find yourself reflecting on whether a single choice will meet diverse demands. It’s essential to gather data on expected loads and consult relevant standards before making a selection. Proper analysis helps avoid future issues.

| Diameter (mm) | Length (mm) | Load Capacity (kN) | Strength Grade | Material |

|---|---|---|---|---|

| 8 | 25 | 10 | 8.8 | Carbon Steel |

| 10 | 30 | 15 | 10.9 | Alloy Steel |

| 12 | 40 | 25 | 12.9 | Stainless Steel |

| 16 | 50 | 35 | 8.8 | Titanium |

| 20 | 60 | 45 | 10.9 | Carbon Steel |

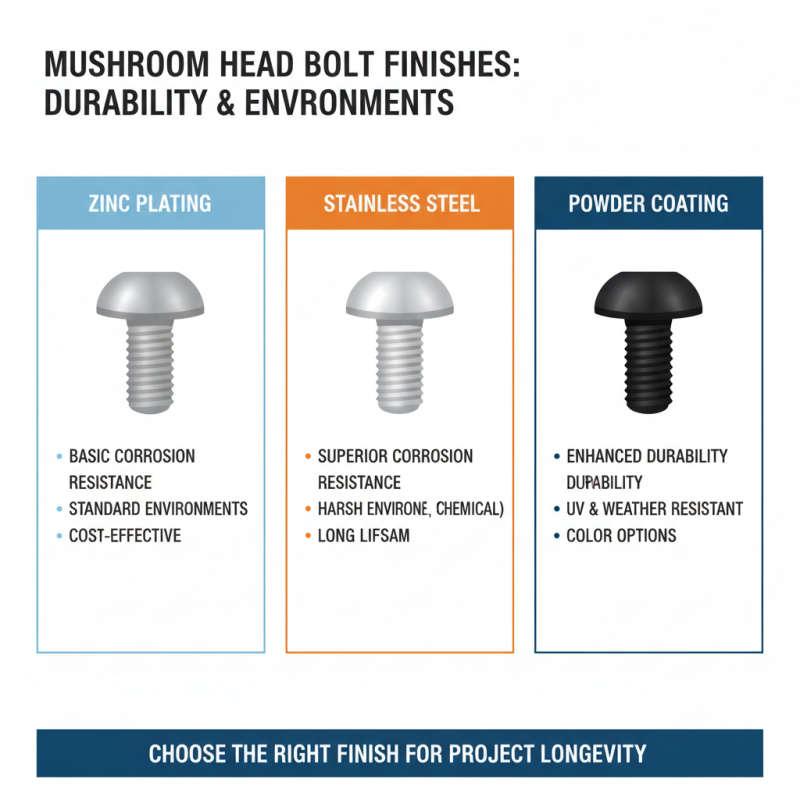

When selecting mushroom head bolts, the finishing options are crucial. Durability is often tied to surface treatment. Common finishes include zinc plating, which offers basic corrosion resistance. However, for projects exposed to harsher environments, consider options like stainless steel or powder coating. These finishes can enhance a bolt's lifespan significantly.

A study from the Fastener Quality Act shows that properly finished bolts can last up to 50% longer in aggressive conditions. Yet, some common finishes might not be suitable for all applications. If the project involves frequent exposure to moisture, neglecting to choose the right finish can lead to rust and failures. Additionally, aesthetics play a role in selection. A shiny finish might be visually appealing, but it can mask underlying weaknesses.

Consider the setting of the project. Is it indoor or outdoor? Will it be viewed frequently? Visual attributes should not overshadow functionality. Sometimes, a dull finish is better for long-term use. Assessing the environment where the bolts will be used can lead to improved choices. Remember that an attractive bolt is of little use if it fails when needed. Balancing durability with aesthetics takes careful thought.