Inquiry

Form loading...

In the world of mining, the importance of the Mining Drill Bit cannot be overstated. According to expert John Smith, a leading authority in drilling technology, "Without a proper Mining Drill Bit, efficiency plummets." This statement emphasizes the crucial role these tools play in mineral extraction.

Mining Drill Bits are designed to penetrate tough materials. Their effectiveness can determine the success of an entire operation. A high-quality bit can reduce downtime and increase productivity. However, not all bits are created equal. The choice of the right bit involves careful consideration of terrain and mineral type.

Many operators overlook the significance of selecting the appropriate drill bit. They assume that any bit will suffice. This could lead to failures and increased costs. Understanding the specific needs of each drilling project is vital. The Mining Drill Bit is not just a tool; it is the lifeblood of successful mining operations.

Mining drill bits play a critical role in resource extraction efficiency. These bits are designed to penetrate tough materials like rock and soil. Their effectiveness directly affects the speed of drilling operations. A well-chosen drill bit can make a significant difference in productivity.

Different types of drill bits are used for various applications. For instance, some are engineered for soft rock, while others are meant for hard surfaces. Selecting the right bit impacts both cost and time. Sometimes, miners may choose a less suitable bit, leading to inefficiencies. This misstep can slow down extraction processes.

Moreover, the wear and tear on drill bits should not be ignored. Over time, bits lose sharpness, which can increase operational costs. Regular maintenance and timely replacements are crucial. Improvements in bit design are ongoing, yet challenges remain. Experimenting with new materials and designs is essential for future advancements.

Mining drill bits play a critical role in the efficiency of mining operations. There are several types, each serving different purposes. For example, diamond bits are known for their hardness. They excel in drilling through tough materials like granite. In contrast, roller bits are great for softer rock formations. They optimize speed and reduce operational costs.

Understanding the specific applications can enhance productivity. The right drill bit can cut through rock more efficiently, saving time and resources. Be sure to choose bits based on the terrain you’re working with.

Tips: Always assess the rock type before selecting a bit. This can prevent unnecessary wear and tear. Regularly check your drill bits for damage. A small crack can lead to bigger issues later. The choice of bit can make or break an operation. Adapt your selection as conditions change.

| Type of Drill Bit | Material | Application | Advantages |

|---|---|---|---|

| Diamond Drill Bits | Synthetic Diamond | Hard Rock Mining | High durability and precision |

| Tricone Bits | Steel and Tungsten Carbide | Oil and Gas Exploration | Versatile and effective in various rock formations |

| PDC Bits | Polycrystalline Diamond | Mineral Exploration | Longer lifespan and faster penetration rates |

| Auger Bits | Steel | Shallow Mining | Simple design and effective for soft materials |

| Hammer Bits | Steel | Quarrying | Effective for breaking hard materials |

When selecting mining drill bits, several key factors come into play. The type of rock formation is paramount. Hard rock requires tougher bits. In contrast, softer materials can benefit from different designs. According to industry reports, 70% of drilling efficiency depends on bit selection. This statistic underscores the importance of matching the right bit to the geological conditions.

Tip: Always analyze the drill site thoroughly. This helps in making an informed decision. Knowledge about rock hardness, abrasiveness, and other variables aids in optimal bit selection. Additionally, consider the drilling method. Rotary, percussive, or hybrid techniques may require distinct bit characteristics.

Wear rate is another critical factor. Bits that wear quickly can lead to increased costs and downtime. A well-designed bit can last longer and perform better under pressure. Many companies emphasize choosing durable materials, yet the market is flooded with options. Reflecting on this can feel overwhelming. Trust industry data and expert recommendations while evaluating durability.

Tip: Regularly review performance data. This helps in refining future choices and minimizing risks. Keep a log of each bit's performance. It's an effective strategy for learning from past experiences. This practice connects theory with hands-on results and benefits the overall mining process.

This chart illustrates the various factors that influence the selection of mining drill bits, highlighting their importance in effective mining operations.

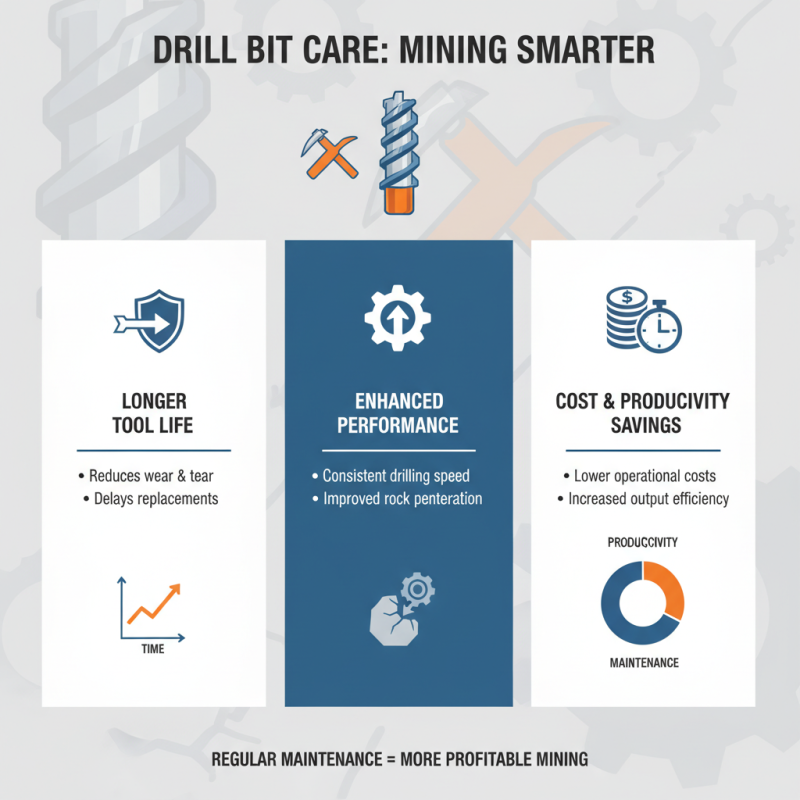

Maintaining drill bits is crucial for effective mining operations. Regular care ensures that these tools last longer and perform better. Proper maintenance can save costs and improve productivity in the long run.

One essential practice is to regularly inspect drill bits for wear and damage. Small chips or cracks can lead to bigger issues. Cleaning drill bits after use also helps maintain their integrity. Dirt and debris can impair performance, causing inefficient drilling. Lubrication is necessary to reduce friction and heat, which can wear down bits quickly.

Storing drill bits correctly is often overlooked. They should be kept in a dry place to prevent corrosion. However, not all miners take care of storage. Ignoring these details can lead to premature wear. Being proactive with maintenance goes a long way in ensuring drill bits remain effective.

Mining drill bit technology has evolved significantly. Innovations are crucial for improving efficiency. Advanced materials and designs enhance their durability. Utilizing synthetic diamonds or carbide can extend the lifespan of these tools. These materials allow for deeper drilling and faster penetration rates. The result is a more productive mining operation.

The impact of technology on drill bits is profound. New designs improve rock penetration and reduce downtime. Moreover, automated drill bits offer precision that was previously unattainable. However, adapting to this technology requires training and adjustments from workers. There is a gap between innovation and execution. Some drills still operate on outdated methods, limiting potential benefits.

Moreover, the sustainability aspect cannot be ignored. As mining practices change, focusing on eco-friendly materials is essential. The industry faces scrutiny over environmental impacts. Rethinking the materials used in drill bits may lead to a greener solution. While advancements are beneficial, they also bring new challenges that need addressing. Balancing efficiency with sustainability is an ongoing struggle.