Inquiry

Form loading...

When embarking on a woodworking project, one of the critical components that can significantly affect its durability and stability is the selection of the right fasteners. Among these fasteners, Timber Bolts play a pivotal role in ensuring that structures remain intact and secure over time. Timber Bolts are specifically designed to provide high strength in wood applications, making them an essential choice for both amateur woodworkers and seasoned professionals alike.

However, with the multitude of options available in the market, choosing the right Timber Bolts can often seem overwhelming. Factors such as material compatibility, size, threading, and coating can all influence the performance and longevity of your construction. Understanding these elements is crucial for achieving successful outcomes in any wood project.

In this discussion, we will explore ten essential tips that will guide you in selecting the ideal Timber Bolts for your specific needs. Whether you're constructing furniture, decking, or any wooden structure, having the right fastening solutions can mean the difference between a project that stands the test of time and one that falls short. Armed with the right knowledge, you can make informed decisions and ensure your projects are both safe and long-lasting.

When selecting timber bolts for construction or woodworking projects, understanding the specifications—grip, length, and diameter—is crucial for ensuring structural integrity and reliability. Grip refers to the effective surface area that can provide resistance against shear forces, which is essential in applications where the joint must withstand significant loads. According to industry standards, an optimal grip length should generally be at least 2.5 times the diameter of the bolt in order to maximize holding strength. Additionally, the choice of grip type, such as coarse or fine threads, can affect the ease of installation and the overall stability of the joint.

The length of the timber bolt is equally important and should be evaluated based on the thickness of the materials being joined. The American Institute of Timber Construction suggests that for every inch of material thickness, an additional 1 to 1.5 inches of bolt length is appropriate to ensure adequate penetration and secure fastening. This ensures a firm connection that accounts for the characteristics of the wood, such as grain direction and density, which can significantly influence the bolt's performance under stress.

Finally, the bolt's diameter is a critical factor that affects the load-bearing capacity and the type of joint created. Data from the Structural Engineering Institute indicates that bolts with diameters ranging from 1/4 inch to 1 inch can accommodate various load requirements. However, it is essential to select diameters that complement the project’s design specifications, as larger bolts provide greater strength but can also lead to increased splitting in timber if not properly installed. By carefully considering these specifications, contractors can make informed decisions that enhance the durability and success of their projects.

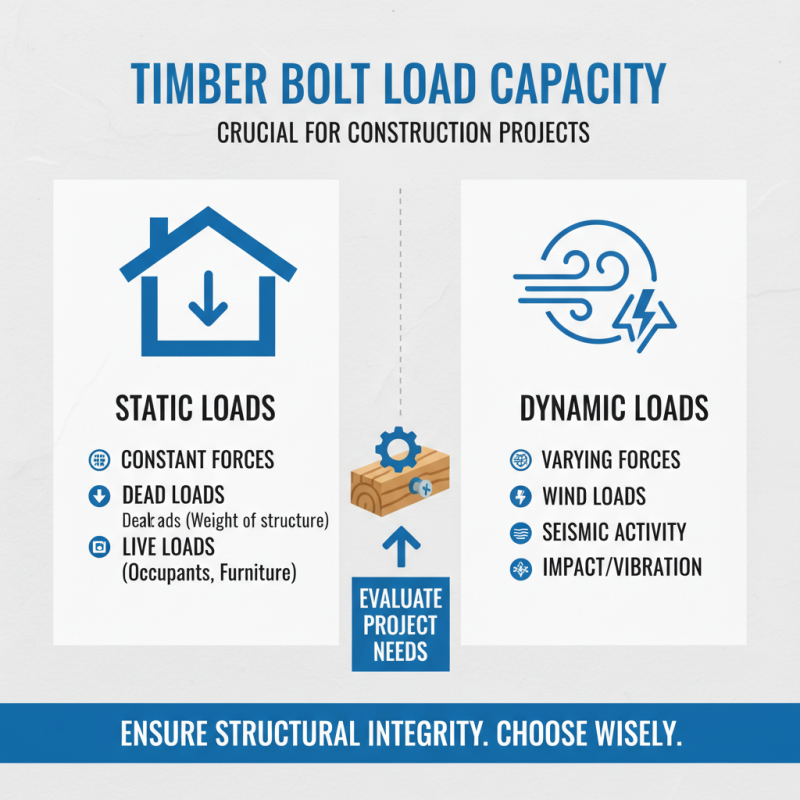

When selecting timber bolts for construction projects, evaluating the load-bearing capacity is crucial. Timber bolts are often subjected to a variety of forces depending on the design and function of the structure they are used in. Understanding the load-bearing requirements specific to your project involves assessing both the static and dynamic loads the bolts will need to withstand. Static loads are those that are constant and do not change over time, while dynamic loads can vary, such as those encountered during high winds or seismic activities.

Safety factors play a significant role in determining the appropriate size and strength of the timber bolts. It's essential to incorporate a safety factor into calculations, which typically ranges from 1.5 to 3, depending on the application's nature and potential risks. For instance, in applications where greater forces are expected or where failure could have serious repercussions, opting for a higher safety factor provides additional assurance. By carefully considering the load-bearing capacity and safety factors, you ensure that the timber bolts selected will perform reliably and safely under the demands of your specific project.

When choosing timber bolts for your projects, material selection plays a crucial role in ensuring durability and long-term performance. The two most commonly used materials for timber bolts are stainless steel and carbon steel. Each has its advantages, and understanding these can help you make the best choice for your needs.

Stainless steel is known for its excellent corrosion resistance, making it ideal for use in external environments or where moisture is present. This material maintains its strength and integrity over time, even when exposed to harsh conditions.

On the other hand, carbon steel offers high tensile strength and is more economical, making it a good option for indoor projects or applications where exposure to the elements is minimal.

When selecting timber bolts, consider the specific conditions they will face. For outdoor projects, opt for stainless steel to avoid rust and degradation. For indoor applications, carbon steel may be sufficient and budget-friendly.

Always ensure the bolts you choose meet the strength requirements of your project and are compatible with the timber being used. Paying attention to these details will lead to more robust and reliable constructions.

When selecting timber bolts for your projects, understanding the importance of corrosion resistance is paramount. Timber bolts are often exposed to various environmental factors, including moisture, humidity, and temperature fluctuations. These conditions can significantly affect their longevity and functionality. Therefore, coatings and treatments are critical to enhance the corrosion resistance of the bolts, ensuring that they maintain their structural integrity over time.

There are several types of coatings and treatments available, each designed to provide a specific level of protection against corrosion. For instance, hot-dip galvanizing involves immersing the bolts in molten zinc, creating a robust barrier against moisture and corrosive elements. Additionally, electroplated coatings can offer a thinner layer of protection while maintaining aesthetic appeal.

It's essential to consider the specific environment where the bolts will be used and select the appropriate treatment that matches the project’s requirements. By prioritizing corrosion resistance through proper coatings, project builders can ensure the durability and reliability of their timber structures for years to come.

When it comes to installing timber bolts, using the right techniques is crucial for achieving a secure and long-lasting fit. One of the best practices is to ensure that the holes for the bolts are drilled accurately. Using a drill with the appropriate size bit will create a snug fit for the bolts, preventing any unnecessary movement that could weaken the joint over time. Additionally, always make sure to drill straight and at the correct depth to avoid compromising the integrity of the timber.

Incorporating the right timber bolts into your project is equally important. For instance, consider the load your structure will bear; choose bolts that can support the weight and stress involved. Furthermore, always opt for corrosion-resistant materials, especially for outdoor projects, to enhance durability. Ensuring that your bolts are installed at the correct torque specifications can also significantly increase the reliability of the connection. It's wise to use a torque wrench to prevent overtightening, which can lead to splitting the wood or damaging the bolt.

Lastly, regular maintenance and inspection of the bolts should not be overlooked. Over time, environmental changes can affect the timber and its fasteners, leading to potential loosening. It's advisable to check the fittings periodically and re-tighten them as necessary, ensuring a safe and stable construction throughout its lifespan.

This bar chart illustrates the importance rating for various factors to consider when selecting timber bolts and their installation techniques. Each factor is rated on a scale from 1 to 10, highlighting the critical aspects for a secure and effective fit in timber projects.