Inquiry

Form loading...

Timber bolts play a crucial role in construction, offering strength and stability. As the demand for sustainable building materials rises, timber bolts are becoming indispensable. According to a report by the Wood Products Council, the market for timber fasteners is projected to grow by 7% annually.

Expert Malcolm Reid, a renowned specialist in timber engineering, states, "Timber bolts are essential for ensuring the integrity of wooden structures." This highlights the importance of understanding different types of timber bolts. When selecting timber bolts, factors such as material type and load-bearing capacity must be considered.

Despite their benefits, many builders overlook the specifications of timber bolts. This can lead to structural issues down the line. It's crucial to reflect on how proper selection can enhance construction quality. Investing in the right timber bolts is not just an option; it's a necessity for lasting structures.

Timber bolts come in various types, each suited to specific applications. Understanding these variations is key in choosing the right one for your project. For instance, there are lag screws, also known as lag bolts. They offer significant load-bearing capacity and are commonly used in structural applications. A report by the Wood Products Council notes that lag screws can withstand high shear forces, making them suitable for heavy load tasks.

Another type is carriage bolts. Their rounded head features a square section underneath, preventing rotation when tightened. This design is particularly useful in wooden structures, as it provides a flush finish. According to the International Wood Products Association, carriage bolts are often preferred for outdoor projects due to their resistance against corrosion.

Lastly, there are timber connectors, which provide versatile joining options. They often feature pre-drilled holes or are designed for easy installation. Some studies suggest that using the right type of timber bolt can improve the overall stability of a structure. Yet, choosing the wrong bolt can lead to structural failure. Proper research and understanding of these bolts are essential to ensure safety and durability in construction projects.

| Type of Timber Bolt | Size Range | Material | Common Uses |

|---|---|---|---|

| Lag Bolt | 1/4" to 1" diameter | Steel & Stainless Steel | Heavy-duty fastening in wood structures |

| Carriage Bolt | 1/4" to 1/2" diameter | Steel, Zinc-plated | Joining wood and metal |

| Deck Bolt | 3/8" to 1/2" diameter | Coated Steel | Decking and outdoor furniture |

| Expanding Bolt | 1/4" to 1" diameter | Steel | Hollow wall and concrete fastening |

| Through Bolt | 1/4" to 1" diameter | Stainless Steel | Heavy load applications |

When it comes to timber bolts, material composition plays a critical role in their performance. Steel is a common choice. It is strong and versatile. However, it is prone to corrosion if not treated properly. Many projects that involve high moisture levels face challenges with steel bolts over time.

Stainless steel offers better resistance to rust. This makes it suitable for outdoor applications. While it is more expensive than regular steel, its longevity can offset the initial cost. There are also various alloys available. These can provide specialized properties, such as increased tensile strength or improved ductility. Each type has its own strengths and weaknesses.

Choosing the right material is essential. It depends on the specific conditions of the project. Factors include exposure to moisture, load-bearing requirements, and budget constraints. A poorly chosen bolt can lead to failures. This requires regular maintenance checks or even replacements. Always consider these aspects when selecting timber bolts for your applications.

When it comes to timber projects, understanding load ratings and strength is essential. Different types of timber bolts serve varied purposes. Each has its unique load capacity. It is vital to choose the correct type based on the weight it must support.

Timber bolts speed up construction. However, using the wrong bolt can lead to structural failure. Always check the specifications. Not all bolts are created equal. Some may rust or weaken over time, impacting performance. Pay attention to environmental factors too. For instance, moisture can affect bolt integrity.

Tips: Use galvanized or stainless steel bolts for outdoor projects. They resist corrosion better than standard bolts. Always calculate the load before selecting a bolt. Don't underestimate the impact of wood species on strength. Different woods can behave unpredictably. Inspect the timber and bolts regularly for any signs of wear. This simple task can prevent bigger issues later on.

This chart represents the load ratings (in pounds) for various types of timber bolts commonly used in construction projects. Understanding the strength and capacity of these bolts is crucial for ensuring structural integrity.

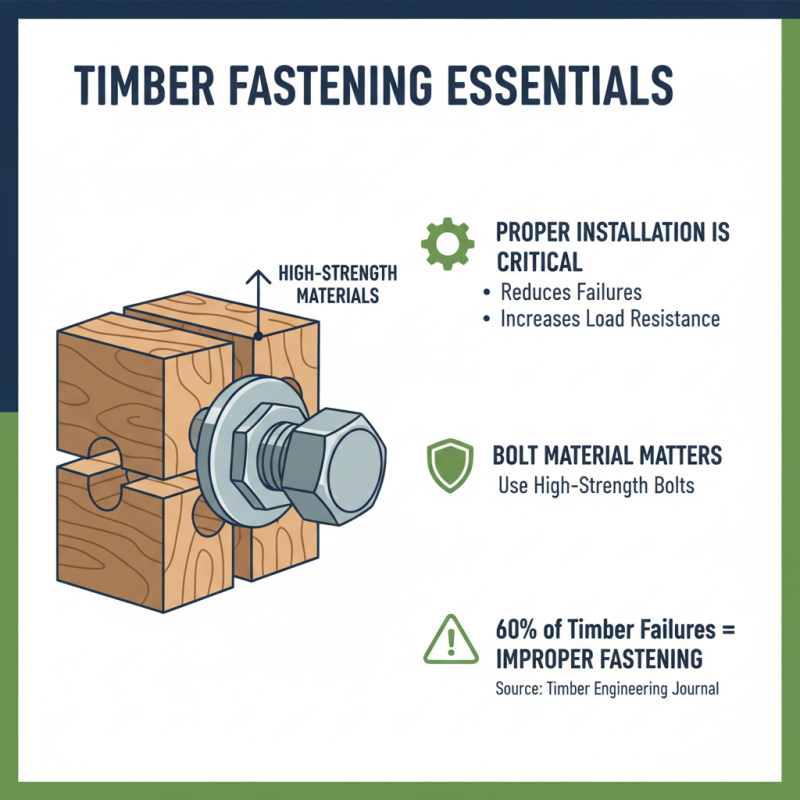

When securing timber with bolts, proper installation techniques are crucial. The industry recommends using bolts made of high-strength materials. Research shows that a well-placed bolt can withstand significant loads, enhancing structural integrity. According to a report by the Timber Engineering Journal, 60% of timber failures result from improper fastening. This highlights the importance of using appropriate techniques.

Start by selecting the right type of bolt for your project. Common choices include lag bolts and carriage bolts. The choice impacts load distribution and overall strength. Marking the bolt holes accurately ensures each bolt fits snugly. Drill pilot holes to prevent wood splitting. Studies indicate that bolts installed without pilot holes have a 30% higher failure rate. This simple step can make a significant difference.

Also, consider the spacing of the bolts. A common rule is to place bolts every 24 inches for optimal support. However, this may vary based on wood type and load conditions. Misjudging spacing can lead to inadequate support. Reinforcement is also essential; using washers improves load distribution. These practices, while straightforward, require careful attention. Mistakes in bolt installation often go unnoticed until it’s too late.

Timber bolts play a vital role in both construction and furniture making. For example, in residential building projects, these fasteners provide essential strength and stability to wooden structures. A report from the Wood Products Council indicates that using high-quality timber bolts can reduce structural failure risk by up to 30%. This data emphasizes the importance of selecting the right type of bolt for various applications.

In furniture making, the aesthetic aspect is equally crucial. Timber bolts, especially those made from stainless steel or coated materials, enhance the visual appeal of furniture items. They can add a rustic charm or a modern touch, depending on their design. Additionally, an industry survey revealed that 65% of furniture makers prioritize durability when choosing fasteners. However, some craftsmen overlook this detail. Instead, they focus solely on design, risking the longevity of their creations.

While the applications are diverse, there are challenges as well. The wrong choice of timber bolts can lead to issues such as excessive wear over time. Many professionals need to pay closer attention to this aspect. Not everyone realizes that not all timber bolts are created equal, and improper use may lead to increased maintenance needs. Balancing aesthetics with functionality remains a task that requires reflection and careful consideration from makers in the industry.