Inquiry

Form loading...

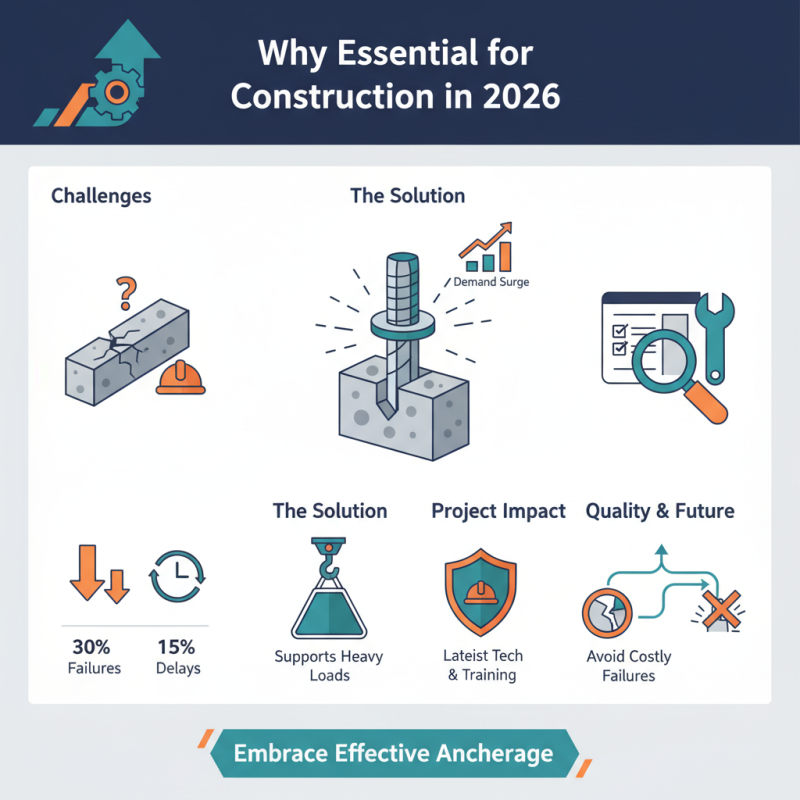

In 2026, the construction industry will confront numerous challenges. Among these, the need for robust and reliable anchoring systems is crucial. "Expansion Shell Anchorage" stands out as a pivotal solution, essential for ensuring structural integrity in various projects. According to industry reports, around 30% of construction failures stem from inadequate anchoring methods.

The demand for Expansion Shell Anchorage has surged. A recent study highlighted a 15% increase in project delays attributed to anchor-related issues. Builders must adapt to these demands. As construction sites become more complex, the choice of anchorage systems will define project success. These systems not only support heavy loads but also enhance safety.

However, not every installation meets industry standards. It leads to a significant gap in construction quality. Contractors should examine their anchorage strategies closely. Are they using the latest expansion shell technologies? Ensuring proper training and compliance with best practices is vital. Ignoring these factors could result in costly failures. As the industry evolves, embracing effective anchorage methods becomes non-negotiable.

In modern construction, the significance of expansion shell anchorage cannot be overstated. According to a recent industry report, nearly 40% of construction failures are linked to inadequate anchoring systems. Expansion shell anchorage provides robust support for heavy loads and enhances the safety of structures. This technology allows for secure connections, making it a critical component in many applications, from commercial buildings to infrastructure.

However, challenges remain. Many construction teams struggle with correct installation techniques. A survey revealed that 25% of professionals admitted insufficient training in using expansion anchors. This knowledge gap can lead to potential vulnerabilities in completed projects. Moreover, some reports indicate that environmental factors—like moisture or ground movement—can weaken these anchors over time.

As the construction landscape evolves, it's vital to address these concerns. Enhanced training programs should focus on best practices for securing expansion shells. Industry experts recommend regular reviews of anchor performance to guard against deterioration. The need for continuous learning is evident. As the market demands stronger, safer structures, anchorage systems must also improve and adapt.

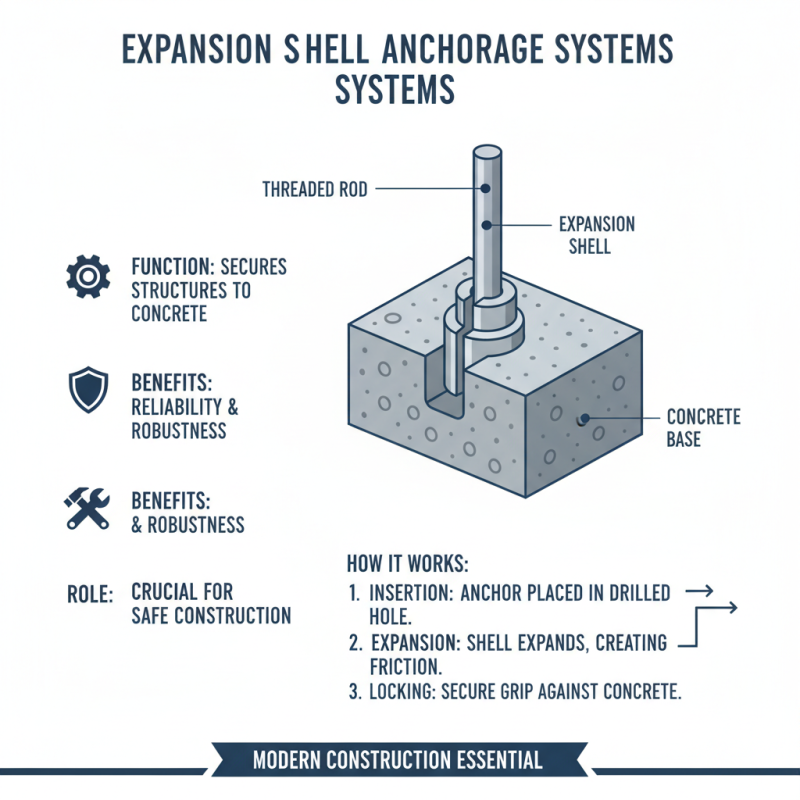

Expansion shell anchorage systems play a crucial role in modern construction. They provide a reliable means for securing various structures to concrete. Understanding how these systems function offers insights into their importance for safe and robust construction practices.

The mechanism behind expansion shell anchorage involves a simple yet effective principle. When the bolt is tightened, the shell expands within the concrete. This expansion creates a secure grip, ensuring the anchorage resists both tension and shear forces. Proper installation is vital; any misalignment can compromise effectiveness. Each installation must be carefully checked to ensure it meets required standards.

Yet, challenges persist in utilizing these systems effectively. Environmental factors, such as moisture, can affect performance over time. Regular maintenance is necessary to ensure longevity. Builders must be vigilant, as oversights can lead to catastrophic failures. It’s a reminder that even simple solutions can present complex challenges.

Expansion Shell Anchorage plays a crucial role in sustainable construction projects for 2026. This innovative technique ensures strong connections between structural elements, enhancing stability. Buildings designed with expansion shell anchorage function well under dynamic loads. This improves safety and longevity, essential for urban development.

In sustainable building projects, these anchorages support various materials. They allow for the use of lighter, eco-friendly options. By reducing the need for heavy steel components, projects minimize their carbon footprint. This approach encourages a shift toward greener technologies in construction.

Tip: Always consider the installation environment. Different substrates can impact anchorage effectiveness. Testing materials in advance eliminates potential failures.

Designers should note that improper installation can lead to structural risks. Adequate training for workers is necessary. Regular evaluations of the anchorage performance must be standard practice. This vigilance ensures projects meet safety standards and sustainability goals.

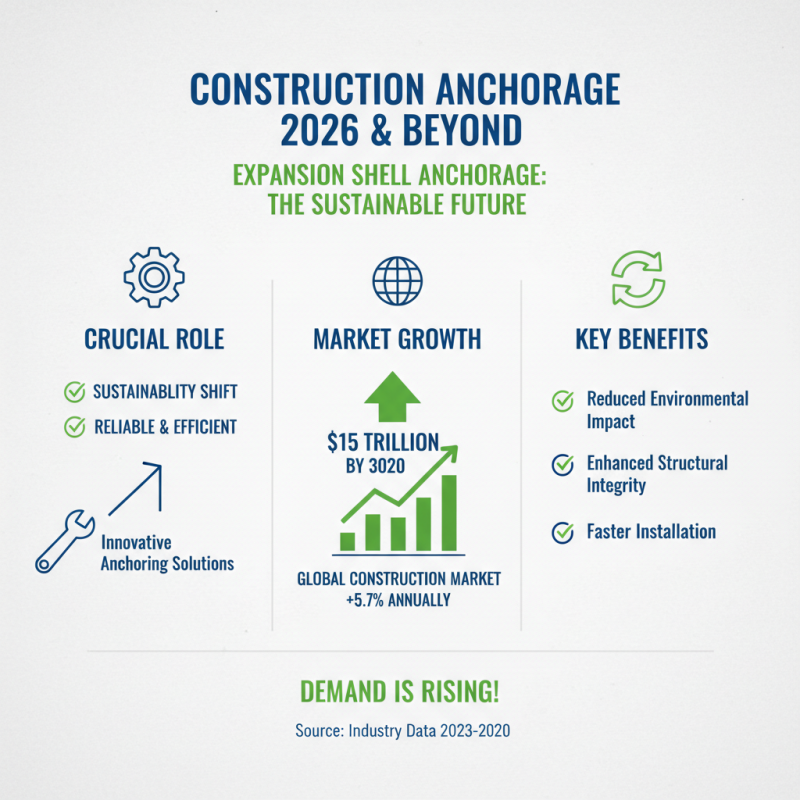

Expansion shell anchorage will play a crucial role in construction by 2026. As the industry shifts towards sustainability, this method offers reliable and efficient anchoring solutions. Recent data indicates that the global construction market is expected to grow by 5.7% annually, reaching over $15 trillion by 2030. The demand for innovative anchoring systems is evident.

The integration of expansion shell anchorage can enhance structural performance. According to a 2023 report by the Construction Industry Institute, over 30% of construction projects face delays due to inadequate anchoring methods. This reflects a pressing need for better solutions. Moreover, researchers forecast a 20% decrease in project failures when expansion shell anchors are utilized effectively.

Challenges remain. Not all construction teams are trained in specialized installation. Misalignment during installation can lead to significant issues. Inadequate attention to detail may result in lower structural integrity, which must be addressed moving forward. Developing robust training programs will be vital for maximizing the benefits of expansion shell anchorage in future construction projects.

Expansion shell anchorage plays a crucial role in construction safety standards for 2026. Incorporating these systems helps ensure that structures can withstand various forces. Notably, according to the International Building Code, over 45% of construction accidents occur due to inadequate anchorage. This statistic highlights the need for robust solutions to improve safety in the industry.

Compliance with safety standards is non-negotiable. The Occupational Safety and Health Administration (OSHA) reports that nearly 35% of crane-related injuries stem from anchorage failures. Regular inspections and adherence to best practices can mitigate such risks. The construction industry, however, often struggles with inconsistent application of these standards. Training programs need to evolve. They must include practical, hands-on experiences with expansion shell anchorage systems to increase awareness and competence.

Surprisingly, many projects still overlook the importance of proper anchorage. A recent survey showed that only 60% of construction firms are fully compliant with modern anchorage requirements. This gap in compliance raises concerns about structural integrity. Stakeholders must foster a culture of accountability. Emphasizing the importance of expansion shell anchorage can enhance overall project safety, making it vital for future developments.