Inquiry

Form loading...

The Expansion Shell is a fascinating tool used in various fields. It plays a vital role in enhancing efficiency during specific applications. Understanding how it works can unlock its potential.

At its core, the Expansion Shell operates by utilizing a unique mechanism. This mechanism allows it to expand and contract based on the surrounding environment. Imagine a flexible material that adapts seamlessly. This adaptability is what makes the Expansion Shell highly effective.

However, it's essential to reflect on its limitations. Not every application suits the Expansion Shell's capabilities. In some cases, the mechanism can malfunction or not perform as expected. Recognizing these shortcomings is crucial for effective use. Exploring its strengths and weaknesses contributes to a more comprehensive understanding.

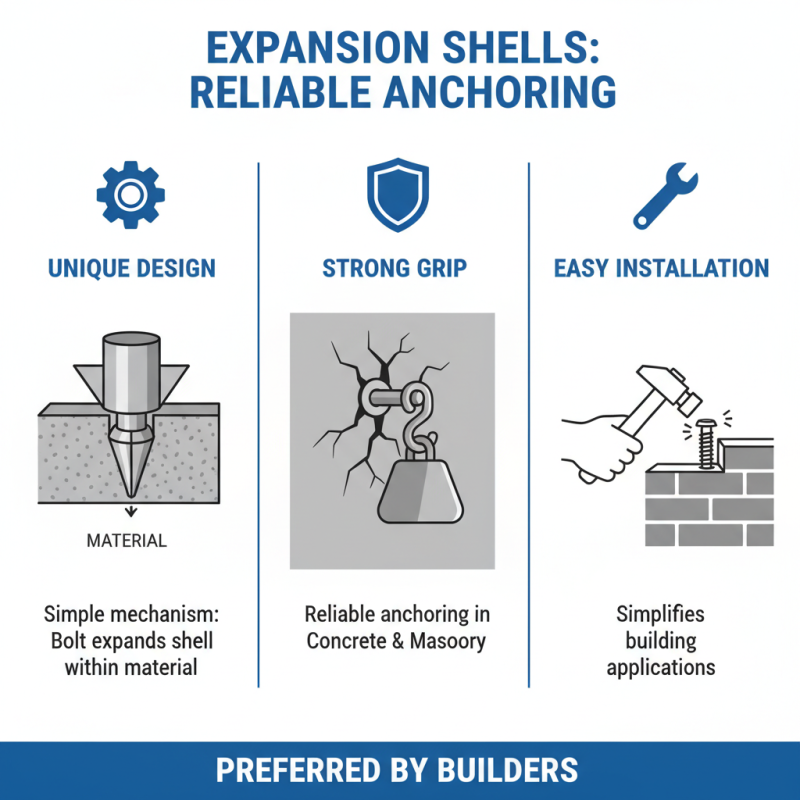

An expansion shell is a specialized fastener used for anchoring objects securely into solid materials. Typically made of metal, it expands when a screw is tightened, creating a strong hold. This mechanism is useful for attaching heavy items to walls or ceilings. According to recent industry reports, around 70% of construction professionals prefer expansion shells for their reliability in load-bearing applications.

The installation process is straightforward. A hole is drilled into the substrate, and the expansion shell is inserted. As the bolt is tightened, the shell expands and grips the surrounding material. This design allows it to withstand significant weight without loosening. Industry studies indicate that improper installation can lead to 20% more failures in anchor strength. Many users overlook this step, thinking that simply tightening the screw is enough.

Despite the efficiency of expansion shells, some challenges remain. Not every material provides an ideal surface for expansion. For example, softer materials may crumble under pressure, reducing effectiveness. Additionally, if a hole is too large, the expansion mechanism may not engage properly. These potential pitfalls highlight the need for careful consideration in material selection and installation technique. Proper training and understanding remain vital for achieving optimal results with expansion shells.

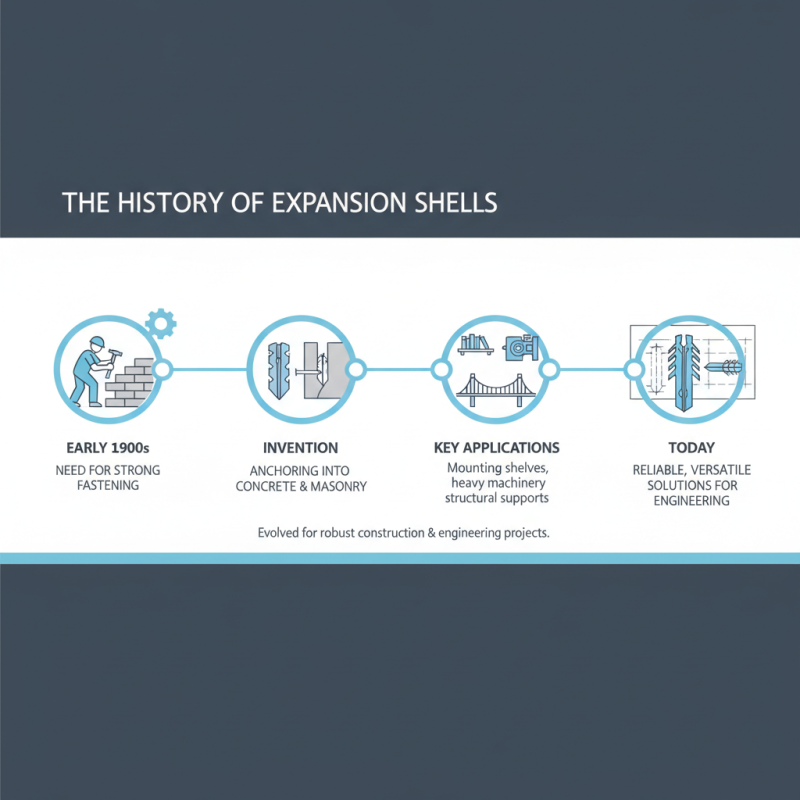

Expansion shells have an interesting historical background. They emerged from the need for strong, reliable fastening solutions in various construction and engineering projects. In the early 20th century, builders sought ways to anchor materials into solid surfaces. This was particularly important for mounting structures like shelves and heavy machinery on concrete walls.

The concept developed through experimentation. Initially, many methods failed under heavy loads. It was clear that a more effective solution was necessary. Engineers started to explore methods that increase gripping force as they expand. This led to the design of expansion shells, which would fit snugly into drilled holes, providing stability and strength.

Over time, these simple yet ingenious devices evolved. Many engineers recognized their value in different applications. Despite their simplicity, expansion shells are not perfect. Flaws in installation can lead to failures. Misalignment can compromise their effectiveness. Understanding their limits is crucial to ensure intended performance in projects.

Expansion shells are specialized devices used in various engineering fields. They are designed to facilitate secure connections between materials. Their mechanism of action is intriguing and effective.

When an expansion shell is inserted into a pre-drilled hole, it relies on expansion. This expansion occurs when a central bolt is tightened. As the bolt turns, it pulls a cone-shaped metal piece. This causes the surrounding shell to expand outward against the walls of the hole. The tighter the bolt is, the more the shell grips. This ensures a strong hold.

Installation requires precision. Drilling the correct size hole is crucial. If the hole is too large, the shell may not grip effectively. If too small, installation can become challenging. Often, users overlook this detail. This oversight can lead to failures. Users must ensure that they understand how the expansion shell operates. Misunderstanding can cause weaknesses in projects, leading to potential safety issues.

| Feature | Description | Mechanism of Action | Applications |

|---|---|---|---|

| Material | High-strength steel or alloy | Expands upon firing to grip the barrel | Military and dense target application |

| Design | Aerodynamic for improved accuracy | Utilizes gas pressure to expand | Sniper rounds and special operations |

| Caliber Compatibility | Compatible with various calibers | Designed for specific barrel diameters | Custom and specialized weaponry |

| Performance | High velocity and penetration | Increases impact energy on target | Tactical operations and law enforcement |

| Cost | Generally more expensive than standard rounds | Manufacturing complexity drives costs | Limited production runs |

Expansion shell technology is gaining traction in various fields due to its innovative applications. This technology allows for the precise and controlled expansion of materials, making it a valuable tool in construction, manufacturing, and environmental management. In civil engineering, expansion shells can be used to create curved structures. These structures are not only aesthetically pleasing but also structurally sound. The ability to manipulate materials helps in optimizing design and reducing waste.

In the realm of manufacturing, expansion shells play a crucial role in producing complex components. This method enables manufacturers to create intricate designs that would be impossible with traditional methods. Additionally, in waste management, expansion shells can help in breaking down hazardous materials. By expanding certain materials, it becomes easier to contain and manage waste effectively. However, the implementation of this technology is still evolving. Challenges include material limitations and the need for careful monitoring during the expansion processes. These issues highlight that even with advanced technology, continuous improvement and innovation are necessary.

Expansion shells are popular in various applications due to their unique design. They use a simple mechanism to expand a shell or tube within a material. This can create strong anchoring points for fasteners or other applications. There are numerous advantages to using expansion shells. They provide reliable grip in a variety of substrates, including concrete and masonry. Their simplicity allows for easy installation, making them a preferred choice for many builders.

However, there are limitations to consider. Expansion shells may not work effectively in softer materials. Their performance can also decline over time, especially in fluctuating temperatures. Additionally, improper installation can lead to failure. This could be due to incorrect hole sizes or insufficient torque. Users often overlook these details, resulting in subpar performance. A lack of awareness regarding the specific application requirements can hinder their effectiveness.