Inquiry

Form loading...

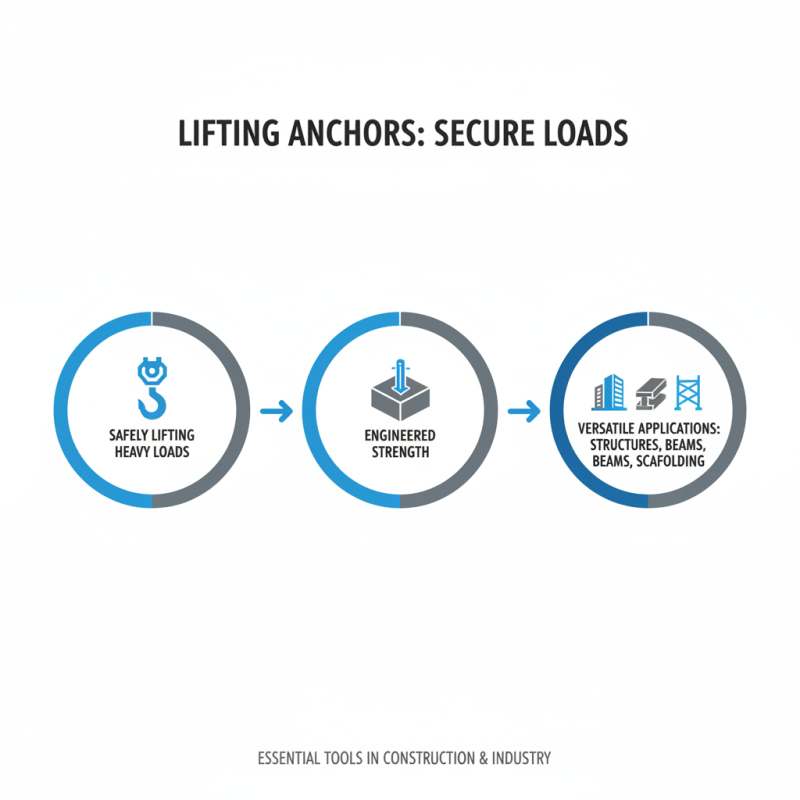

Lifting Anchors play a crucial role in various industries. They are essential for safely securing loads during lifting operations. Understanding how these anchors function can enhance safety and efficiency.

These fixtures are designed to withstand immense forces. They can support heavy materials, ensuring stability during transport. Lifting Anchors come in different types, each suited for specific applications. For example, some are used in industrial settings, while others may serve construction projects.

However, the selection and use of Lifting Anchors are not always straightforward. Mistakes can lead to severe accidents. It is vital to assess the load, the environment, and the anchor type before use. Awareness of potential failure points is crucial for safety. By recognizing these challenges, users can make informed decisions and improve practices.

Lifting anchors are essential devices used to secure and lift heavy loads. Their primary purpose is to provide a reliable point for lifting, especially in construction and heavy machinery operations. The design of lifting anchors allows them to withstand the stresses of pulling forces while ensuring safety and stability.

In industry reports, it is noted that improperly used lifting anchors contribute to nearly 20% of workplace accidents during lifting operations. This highlights the importance of understanding their correct application. For instance, the load capacity of an anchor can vary significantly based on its material, design, and installation method. Aluminum anchors, for instance, are lightweight yet can manage up to 3,000 pounds in some configurations, while steel options can lift loads exceeding 10,000 pounds.

However, not all lifting anchors are created equal. Condition and compatibility matter. Rust, corrosion, and wear can lead to catastrophic failure. It's crucial to inspect lifting anchors routinely. Companies must educate crews on the risks associated with neglect. This vigilance can prevent accidents and improve overall safety in lift operations. Every lifting job requires a thoughtful approach to anchor selection to mitigate risks.

Lifting anchors are crucial components in various industries. They help secure heavy loads for lifting and transportation. There are different types of lifting anchors, each designed for specific applications. Understanding these variants is essential for safety and efficiency.

One common type is the cast-in lifting anchor. This anchor is typically embedded in concrete structures. Its design allows for a strong connection point. According to industry reports, these anchors can handle loads ranging from 1 to 60 tons. However, improper installation can lead to failures. It’s vital for workers to ensure correct placement and alignment.

Another variant is the bolt-on lifting anchor. These anchors are attached to existing structures. They offer flexibility and ease of use. Data suggests that these anchors are used widely in construction and shipping. The load capacity can vary significantly based on the bolt’s strength and the mounting surface. However, relying solely on bolt-on anchors may lead to oversights in load calculations. Engineers need to reevaluate installation conditions regularly.

Lifting anchors are essential components in construction and rigging. They provide stable points for securing loads. Understanding how they work involves delving into their mechanisms and load distribution.

Lifting anchors operate through a system of mechanical design and material strength. The most common types include wedge anchors, sleeve anchors, and eye anchors. When a load is applied, the anchor distributes weight evenly across its surface. According to a report by the International Journal of Engineering Research, properly installed anchors can handle loads up to 30 times their own weight. This means the right installation is crucial for safety.

Moreover, the effectiveness of lifting anchors relies heavily on the surrounding material. For instance, anchors in concrete perform differently than those in soil. As reported by the American Concrete Institute, improper selection can lead to a 40% reduction in load-bearing capacity. Each installation scenario presents unique challenges. This calls for careful planning and consideration to avoid potential failures. Users must frequently reassess anchor conditions to ensure optimal performance.

| Anchor Type | Load Capacity (kN) | Installation Method | Typical Applications |

|---|---|---|---|

| Expansion Anchor | 10 - 50 | Drilled hole and expansion | Concrete and masonry applications |

| Chemical Anchor | 10 - 90 | Epoxy adhesive in drilled hole | Heavy load and seismic applications |

| Straight Shank Anchor | 15 - 60 | Direct embedding | Steel structures and heavy lifting |

| Lift Clamp Anchor | 5 - 30 | Clamping mechanism | Precast concrete handling |

| Composite Anchor | 20 - 100 | Combination methods | Versatile applications in different materials |

Lifting anchors are crucial for safe material handling. When using these devices, safety considerations cannot be overlooked. Each lifting anchor has a specific load rating. This rating indicates the maximum weight it can support without failure. It's vital to consult these ratings before lifting any load. If the anchor is overloaded, it may fail.

Additionally, proper installation is essential. Incorrect placement can lead to accidents. A lifting anchor should be securely fixed to ensure stability. Inspecting the anchor before use can prevent potential mishaps. Operators should remember that environmental factors play a role. Changes in weather or ground conditions can affect anchor performance. Always assess the surroundings when planning a lift.

Training personnel in safe practices is also key. Regular training ensures that workers understand how to use lifting anchors properly. Knowledge of load limits and installation techniques is necessary. A good understanding helps in recognizing when something feels off. It’s important to have a clear communication plan during lifting operations. Miscommunication can lead to dangerous situations, regardless of anchor quality.

Lifting anchors are essential tools in construction and industry. They provide a secure point to lift heavy loads safely. These anchors can be used in various applications, such as hanging structures, lifting beams, or supporting temporary scaffolding. The engineering behind lifting anchors ensures that they can handle substantial weight and stress without failing.

In construction sites, lifting anchors often assist in positioning large materials. They help lift concrete panels or steel beams into place. This efficiency saves time and labor. However, not all anchors are suitable for every job. Users must understand the required load capacity. Miscalculating this can lead to accidents.

Tips: Always check the installation guides for anchors. Regular inspections can prevent unexpected failures. This practice isn’t just about safety; it's about ensuring project quality. Lifting anchors should be inspected for wear and rust.

Industries like shipping and manufacturing also rely on lifting anchors. They can facilitate loading and unloading cargo. In warehouses, anchors help store materials securely. Yet, poorly maintained equipment can lead to dangerous situations. Implement strict maintenance schedules to ensure safety and reliability.