Inquiry

Form loading...

Lock Nuts are essential components in various mechanical applications. They provide a reliable method to secure bolts, preventing loosening due to vibration or stress. Dr. Emily Carter, a leading expert in fastening technologies, states, “Lock Nuts are the unsung heroes in mechanical assembly.” Her insight highlights the importance of these small yet mighty fasteners.

Lock Nuts come in different types, each designed for specific applications. They work by creating friction and resistance against loosening forces. For example, nylon insert lock nuts incorporate a nylon ring that grips the bolt threads. This detail ensures a tight hold, even under challenging conditions. However, choosing the right type can be complex, and mistakes could lead to failures.

While Lock Nuts are crucial for safety and performance, over-reliance on them can be misleading. Some may think they are a catch-all solution. This belief could encourage careless application or installation. In reality, understanding the nuances of Lock Nuts is vital. Complexity exists in selecting the appropriate type and understanding their limitations.

Lock nuts are essential components in various engineering applications. They prevent fasteners from loosening due to vibration or thermal expansion. The design of a lock nut typically involves a prevailing torque feature, which creates resistance during installation and ensures a secure fit.

According to a recent report by the International Fastener Group, around 35% of fastener failures occur due to loosening. This statistic emphasizes the importance of using lock nuts in critical assemblies. Lock nuts come in various designs, including nylon insert nuts and serrated flange nuts. Each type serves a specific purpose based on the application requirements. The right choice can prevent costly downtime and improve safety.

However, it's crucial to recognize that not all lock nuts are created equal. Misapplication can lead to inadequate performance. Over-tightening can compromise their effectiveness, resulting in failure. Engineers need to consider the specific conditions each application presents. Experience plays a significant role in making the right choice. Evaluating environmental factors and load conditions can lead to better outcomes.

| Type of Lock Nut | Description | Applications | Advantages |

|---|---|---|---|

| Nylon Insert Lock Nut | A nut that has a nylon collar inserted into it that increases friction and prevents loosening. | Automotive, machinery, and structural applications. | Effective in preventing vibration loosening, reusable. |

| Castle Nut | A nut with a series of slots cut into one end used with a cotter pin to secure a fastener. | Automotive and heavy equipment applications. | Provides visual indication of tightening, prevents loosening from vibration. |

| Jam Nut | A thin nut that is tightened against another nut to lock them in place. | Used in linkages and assemblies requiring frequent adjustments. | Compact design, easy to use for locking purposes. |

| Locking Washer Nut | A nut that incorporates a built-in washer to prevent loosening. | Applications where high torque is present. | Provides additional grip, designed for high-stress applications. |

| Serrated Flange Nut | A nut that has serrations on its flange that dig into the surface to prevent loosening. | Used in situations where standard flat washers would not hold. | Good grip on softer materials, prevents surface damage. |

Lock nuts are specialized fasteners that prevent loosening due to vibration or dynamic loads. Various types of lock nuts exist, each with distinct applications. Common types include nylon-insert lock nuts, prevailing torque lock nuts, and double nuts. These nuts serve specific functions in different settings.

Nylon-insert lock nuts are ideal for delicate applications. They use a nylon ring to create friction. This design keeps the nut in place without damaging the threads. However, they may not work in extreme temperatures. Ensure you check your environment when using these.

Tips: Always verify the material compatibility. Some metals may react with locking materials.

Prevailing torque lock nuts are made to resist loosening. They have a special design that increases friction. These nuts are suitable in heavy machinery and automotive applications. Yet, incorrect torque may lead to issues. Monitor your torque settings closely.

Tips: Use a torque wrench for better control. An improperly torqued lock nut could lead to failure.

Double nuts consist of two traditional nuts locked together. This design allows for adjustable tension. They are useful in construction or large machinery. But keep an eye on them; they can be tricky to install correctly.

Tips: Always use the right size wrench. A wrong fit can damage the nuts.

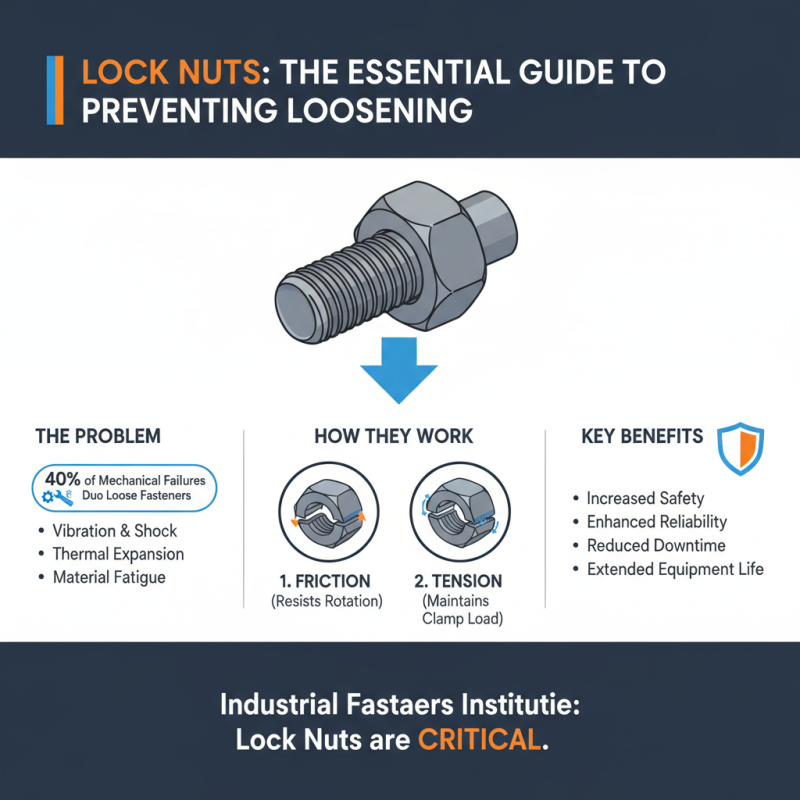

Lock nuts play a vital role in preventing loosening in various applications. These specialized fasteners utilize friction and tension to maintain tight connections. A report from the Industrial Fasteners Institute states that about 40% of mechanical failures are due to loosening fasteners. This highlights the importance of understanding how lock nuts work.

The mechanisms of action in lock nuts are diverse. One common type uses a nylon insert that grips the threads of the bolt, providing resistance against rotation. Another method involves a serrated surface that digs into the connected material. These features ensure that external forces do not easily displace the nut. However, improper installation or wear can compromise this effectiveness. Research shows that environmental factors like temperature fluctuations can cause material expansion, affecting the performance of lock nuts.

Despite their effectiveness, lock nuts are not foolproof. Users must regularly check for proper tension and wear signs. Ignoring these aspects can lead to potential failures. In one survey, 25% of users admitted to neglecting routine maintenance, which increases the risk of loosening. Consequently, understanding both the strengths and limitations of lock nuts is crucial for ensuring reliability in critical applications.

Lock nuts are crucial components in many industries, offering enhanced security and stability in mechanical assemblies. These nuts are designed to prevent loosening from vibration and torque. A report from the International Journal of Advanced Manufacturing Technology shows that using lock nuts can reduce assembly failure rates by up to 30%. This improvement is vital in sectors like automotive and aerospace, where safety and precision are paramount.

The versatility of lock nuts extends to construction and heavy machinery, where harsh conditions can lead to component failure. For example, in construction, loose bolts can result in costly downtime and safety hazards. A survey by the Construction Industry Institute states that rework due to joint failures can account for 10-20% of total project costs. Lock nuts help minimize such risks, improving overall project efficiency.

However, the effectiveness of lock nuts relies on proper installation. Misalignment during installation can lead to issues later. Even with lock nuts, regular maintenance checks are needed. Relying solely on their locking feature without periodic inspections can lead to overlooked problems. Ultimately, while they provide significant advantages, a thorough understanding of their limitations is essential for optimal performance.

Lock nuts are essential components in various mechanical assemblies. Proper installation and maintenance greatly influence their performance. These nuts lock onto bolts to prevent loosening due to vibration or other forces. However, incorrect installation can lead to failure. It’s crucial to ensure the right torque specifications are followed. The International Organization for Standardization (ISO) recommends specific torque values based on the nut and bolt size.

Maintenance of lock nuts involves regular inspection. Check for signs of wear, corrosion, or deformation. Using a certified torque wrench can help maintain proper tension. Studies show that up to 30% of mechanical failures are due to improper fastening techniques. Ensure that the surfaces are clean as dirt can compromise the locking mechanism.

In certain environments, such as high-temperature areas, the choice of material matters. Some lock nuts may experience thermal expansion, which can affect their hold. Learn to recognize the indicators of failures, like unusual noises or vibrations. This is often a sign something is wrong. Regular checks and timely adjustments can save costs down the line. Understanding how lock nuts function in your specific application is key to ensuring longevity and safety.