Inquiry

Form loading...

In the construction industry, understanding "Machine Bolts" is crucial. These fasteners play a vital role in providing strength and stability to structures. As expert engineer John Smith states, "Machine bolts are the backbone of modern construction."

Machine bolts come in various sizes and grades, making them versatile for different applications. They connect steel beams, hold frames together, and secure heavy machinery. Each bolt must be chosen carefully to ensure safety and performance.

However, not all machine bolts are created equal. The quality varies, and using subpar materials can lead to structural failures. Builders must understand this and select bolts that meet specific project requirements. Recognizing the importance of quality can prevent costly mistakes in the long run.

Machine bolts are essential fasteners commonly used in construction. They are designed for heavy-duty applications, which require reliable and strong connections. A machine bolt typically features a blunt end and a threaded shaft. This design helps in engaging with nuts and other components securely. The diameter and length of bolts can vary based on the specific requirements of a project. Industry data suggests that machine bolts can support loads ranging from several hundred to thousands of pounds, depending on their size and material type.

Tips: Always select the right size for your project. A bolt that is too short may not provide the necessary strength. Likewise, an oversized bolt can lead to issues during installation.

The materials used to manufacture machine bolts significantly influence their performance. Common materials include steel, stainless steel, and alloyed metals. Each of these materials has distinct corrosion resistance and tensile strength. For example, stainless steel bolts have superior corrosion resistance but may not perform as well under extreme loads. According to a recent report, about 70% of construction professionals prefer steel bolts due to their balance of strength and cost-effectiveness.

Tips: Regularly inspect machine bolts for wear and corrosion, especially in harsh environments. Neglecting these checks can lead to unexpected failures.

Machine bolts are essential fasteners in construction. They are designed to handle significant loads and provide strong joints. These bolts are commonly used in structural assembly. Their versatility makes them suitable for various applications.

In building bridges, machine bolts are crucial. They hold steel beams together, ensuring stability and safety. In high-rise buildings, they secure structural frames during installation. These installations require precise measurements. A mistake can lead to costly errors.

Machine bolts are also used in machinery and equipment assemblies. They connect parts in heavy machinery, offering strength and durability. However, improper use can weaken the joint. Ensuring the right torque is vital to prevent failure. Regular inspections are necessary to maintain structural integrity. This attention to detail can save time and resources in the long run.

Machine bolts are essential components in construction, providing strong connections in various applications. These bolts come in different grades, which reflect their mechanical properties. Common materials include carbon steel and stainless steel. The choice of material affects strength and corrosion resistance. Ensuring the right material standard is crucial for safety and durability.

Mechanical properties such as tensile strength, yield strength, and elongation must meet specifications. For instance, Grade 8 bolts have higher tensile strength than Grade 5. Builders often overlook the importance of matching bolt properties to project requirements. This can lead to weak joints and structural failures.

Tips: Always verify the material standards for machine bolts. Cross-reference with construction codes to avoid errors. Misusing bolts can compromise the entire structure. Take the time to choose wisely. Make sure to inspect bolts for any defects before use. A small flaw can lead to significant problems later.

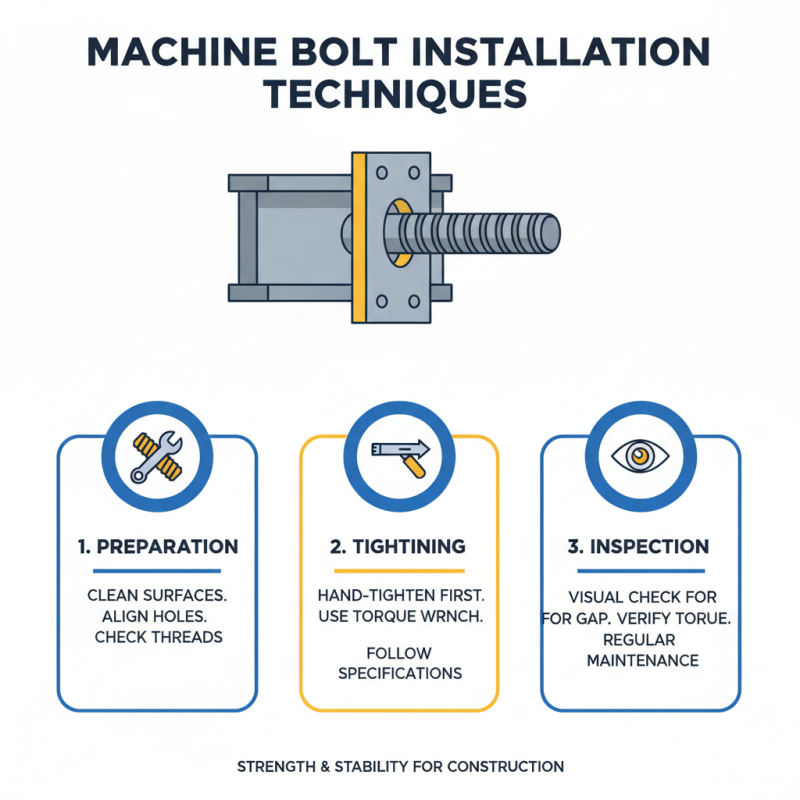

Machine bolts are essential in construction. They provide strength and stability. Proper installation is key to their performance. Here are some effective techniques.

Begin by selecting the right bolt size. Ensure it matches your materials. A bolt that's too long or short can cause issues. Clean the surfaces that will be joined. Dirt or rust can weaken the connection.

When inserting the bolt, use a washer to distribute pressure. This helps in avoiding damage to the materials. Tighten the bolt but avoid over-torquing. Too much force can lead to stripping threads.

Tips: Always double-check your measurements. Misalignment can lead to structural failures. If you're unsure, ask for advice. It’s vital to learn from mistakes. Check the load specifications to ensure safety.

When using machine bolts in construction, safety is paramount. These bolts are essential for fastening structural elements. If not properly installed, they can lead to structural failures. Always ensure that the torque specifications are followed. Over-tightening can cause threading damage. This could compromise the joint. Under-tightening may lead to loosening over time.

Load calculations are crucial when determining the appropriate size of a machine bolt. It’s vital to consider the materials being connected. Different materials have varying load-bearing capacities. Incorrect calculations can result in catastrophic failures. It often requires expert input. Simple estimation can be misleading. Each construction project is unique, demanding careful evaluation.

Moreover, continual inspection is important. Even well-installed bolts can degrade over time due to environmental factors. Regular checks help avoid potential issues. Skipping this step can be a costly mistake. Relying solely on initial installation is risky. Proper maintenance can enhance safety and longevity. Always prioritize diligence and thoughtful assessment in construction practices.

| Dimension | Material | Load Capacity (kN) | Common Uses | Safety Considerations |

|---|---|---|---|---|

| M12 x 60 mm | Steel | 22 | Structural connections | Correct torque settings |

| M16 x 100 mm | Stainless Steel | 32 | Heavy machinery assembly | Corrosion resistance |

| M20 x 150 mm | Alloy Steel | 45 | Bridges and large structures | Ensure proper alignment |

| M10 x 40 mm | Carbon Steel | 12 | Furniture assembly | Check for shear strength |

| M14 x 80 mm | Bronze | 27 | Marine applications | Avoid galvanic corrosion |