Inquiry

Form loading...

In the world of mining, the importance of effective anchoring cannot be overstated. The Mining Expansion Shell Anchor Bolt plays a critical role in ensuring safety and stability in underground operations. According to Dr. Michael Reynolds, a renowned expert in mining engineering, "Proper installation of anchor bolts is vital to preventing structural failures."

When installing Mining Expansion Shell Anchor Bolts, precision is key. Miners must consider rock quality and hole depth. Improper installation can lead to catastrophic outcomes. Understanding the geology of the area is crucial. Tools and techniques used must be adapted to specific conditions.

Despite advancements, many installations still exhibit common flaws. Regular training for personnel is essential for maintaining safety standards. Experts often highlight the need for periodic inspections. Over time, bolts may degrade, demanding close attention. Reflecting on these elements can enhance the overall effectiveness of mining operations.

When working on mining expansion projects, shell anchor bolts are crucial. These bolts secure equipment and structures in place, ensuring stability in challenging environments. Understanding their installation can greatly affect the project’s success. Proper placement is essential to avoid costly repairs and safety issues. Choosing the right bolt length and diameter for your application is vital.

Each site presents unique challenges. Soil conditions vary, which can impact the effectiveness of the anchor bolts. Conducting thorough soil analysis before installation can prevent future problems. If the bolts are not installed deep enough, they may fail under stress. This could lead to equipment damage and project delays, which are costly.

Incorporating quality control measures can enhance the installation process. Regular inspections should be a part of your routine. Train your team to spot installation errors and ensure compliance with safety standards. Remember, even small mistakes can lead to significant issues down the line. Reflecting on past experiences can guide future projects and improve outcomes. Every detail matters in achieving optimal results.

Installing shell anchor bolts in mining operations requires attention to several key factors for optimal performance. One crucial aspect is the substrate condition. A clean and stable surface ensures better adhesion and load distribution. Any debris or loose material can compromise the effectiveness of the installation. Additionally, moisture levels play a significant role. Excess water can weaken the bond and lead to potential failures over time.

Another important factor is the alignment of the bolts. Properly positioning each bolt during installation prevents uneven stress and potential breakage. Regular checks while installing can save time later. Furthermore, consider the torque specifications. Applying the right amount of torque is essential for securing the anchor. Too much can damage the bolt, while too little can result in insufficient holding power.

Installation methods also require reflection and adaptation. Experienced workers often face unexpected challenges. Adjusting techniques on-site can lead to better results. It is vital to analyze the performance of installed bolts periodically. Understanding how different factors affect overall durability is crucial for future projects. Optimal installation may not always be achieved in the first attempt, but learning from each experience strengthens future efforts.

Installing shell anchor bolts correctly is crucial for mining expansions. This process can be daunting, but breaking it into manageable steps helps. Start by selecting a suitable location. Inspect the ground conditions. Ensure it can support the load. Measure the depth and diameter of the hole you need.

Drilling the hole accurately requires careful attention. Maintain the right angle and depth to avoid mishaps. Clean the hole thoroughly to remove dust and debris. This step is often overlooked but is essential for a strong bond. After cleaning, insert the anchor bolt. Pay attention to the orientation. Misalignment can weaken the installation.

Once the bolt is in place, apply the necessary torque. Use a reliable torque wrench for this step. It may take some time to set the correct force. Too much pressure can damage the bolt. Too little can lead to failure. Make sure to double-check the installation. This is a common area where mistakes occur. Refining this process can lead to improved results over time.

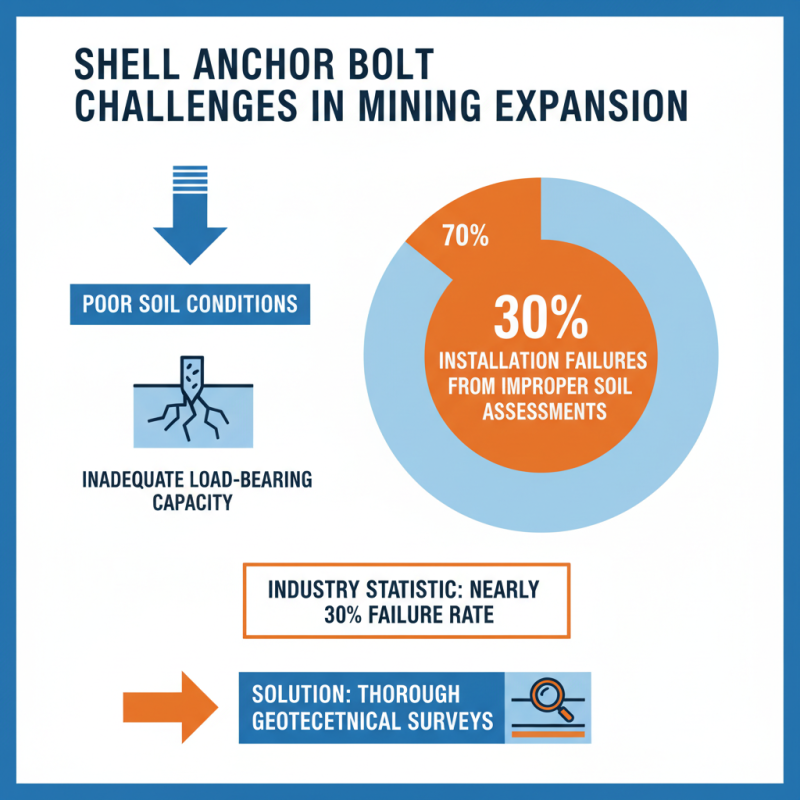

When using shell anchor bolts in mining expansion projects, challenges often arise. Poor soil conditions can lead to inadequate load-bearing capacity. According to industry studies, nearly 30% of installation failures stem from improper soil assessments. This statistic highlights the importance of conducting thorough geotechnical surveys before installation.

Another common issue is the torque applied during installation. Over-tightening can damage the bolt or surrounding rock, while under-tightening may result in loosening over time. A report from the Mining Journal indicates that optimizing torque can improve anchor performance by up to 20%. Regular checks are essential here to ensure the integrity of the installation.

Tips for effective installation include ensuring the hole is clean and free of debris. Always check the alignment of the bolt before securing it. Marking the correct torque value on your equipment can save time during installation. Consistent monitoring is crucial; using a torque wrench designed specifically for shell anchor bolts is advisable. Aim for the recommended specifications in the technical data sheets, but always adapt to the unique conditions at the site.

Maintaining shell anchor bolt installations is crucial for their longevity. Regular inspections can identify wear and tear early. Look for signs of rust or corrosion. These may indicate stress on the bolts. If discovered, act quickly to mitigate potential failures.

Consider environmental factors too. High humidity and salty air can degrade materials over time. Keep the area around the anchors clean. Remove debris that can trap moisture. This simple step can enhance their lifespan.

Another tip is to apply a protective coating. This can provide a barrier against corrosive elements. Check the bolts frequently, especially after heavy usage. Record your findings to track any changes. Reflect on what might cause deterioration. The goal is to maintain optimal performance throughout their service life.

Regular maintenance is essential. Don’t ignore minor issues; they can lead to bigger problems. Prevention is always better than repair.

| Tip | Description | Frequency of Check |

|---|---|---|

| Correct Size Selection | Select anchor bolts that match the load requirements of your specific application. | Before Installation |

| Proper Hole Preparation | Drill holes to the correct diameter and depth to ensure a secure fit. | Before Installation |

| Installation Torque | Apply the recommended torque to avoid under-tightening or over-tightening. | With Each Installation |

| Inspection for Corrosion | Regularly check for signs of corrosion or wear to ensure structural integrity. | Every 6 Months |

| Environmental Considerations | Choose materials that withstand the specific environmental conditions, such as humidity and temperature. | During Initial Setup |

| Load Testing | Conduct load tests to ensure the anchor bolts can handle expected stresses. | Annually |