Inquiry

Form loading...

In the world of fasteners, Mushroom Head Bolts stand out for their unique design and versatile applications. According to John Smith, a leading expert in the fastener industry, “Mushroom Head Bolts are not only aesthetically pleasing but also provide exceptional load-bearing capabilities, making them a preferred choice in various engineering sectors.” These specialized bolts feature a domed head that can distribute load more evenly, thus reducing the risk of damage to the material being fastened.

Mushroom Head Bolts are increasingly being utilized across numerous industries, from automotive to construction, due to their strength and reliability. Their ability to accommodate various types of materials and withstand significant stress makes them an essential component in many applications. As we explore the top ten Mushroom Head Bolts and their benefits, it becomes clear that understanding their functionality can greatly influence the efficiency and safety of engineering projects. Whether you are a DIY enthusiast or a seasoned professional, knowing the ins and outs of Mushroom Head Bolts can enhance your fastening solutions and overall project outcomes.

Mushroom head bolts, characterized by their unique domed tops, are essential fasteners in various applications ranging from furniture assembly to automotive manufacturing. The design allows for a broader bearing surface, which distributes pressure evenly, minimizing the risk of material deformation. These bolts come in various materials including stainless steel, carbon steel, and aluminum, each offering distinct advantages depending on the environment and specific application.

When selecting mushroom head bolts, it’s crucial to consider the material based on the use case. Stainless steel provides excellent corrosion resistance, making it suitable for outdoor applications or in environments prone to moisture. On the other hand, carbon steel offers high strength and durability, perfect for structural applications where bolts are exposed to heavy loads. Aluminum is lightweight and resistant to corrosion, ideal for applications where weight savings are critical.

Tips: Always match the bolt's material and coating with the working environment to ensure long-term durability. Additionally, utilize appropriate torque settings during installation to prevent stripping and ensure the integrity of the assembly. Regular maintenance checks can also help in identifying any signs of wear or corrosion, prolonging the lifespan of your mushroom head bolts.

This chart illustrates the tensile strength of different types of mushroom head bolts made from various materials. The data shows the performance capabilities of these bolts in terms of maximum load they can handle before failing, making it easier to select the right type for specific applications.

Mushroom head bolts have gained significant traction in the construction industry due to their unique design and multifaceted benefits. One of the primary advantages of using mushroom head bolts is their enhanced load distribution capability. The broad, flat head of the bolt helps to spread the load over a larger surface area, significantly reducing the risk of material deformation. According to a report by the International Journal of Engineering Research, using mushroom head bolts can improve joint stability by up to 25% compared to traditional bolt designs, making them a preferred choice for structural applications.

In addition, mushroom head bolts are often favored for their aesthetic appeal and ease of installation. The smooth, rounded head not only provides a clean finish, which is particularly desirable in visible structures, but it also allows for easy handling and alignment during the assembly process. Moreover, industry data indicates that the use of mushroom head bolts can decrease installation time by approximately 15%, leading to increased efficiency on job sites. With their combination of strength, aesthetics, and ease of use, mushroom head bolts have become indispensable in modern construction projects, enhancing both the functionality and appearance of structures.

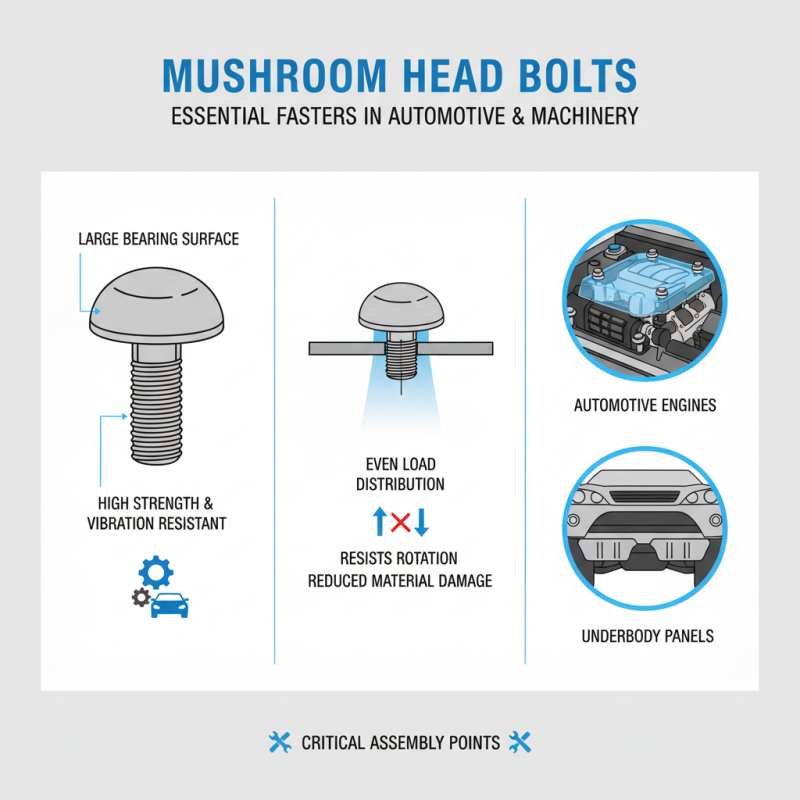

Mushroom head bolts, characterized by their distinctive dome-shaped heads, are essential fasteners in automotive and machinery design. Their design allows for a larger bearing surface, which distributes load evenly and reduces the risk of damage to the materials they fasten. In automotive applications, mushroom head bolts are often used in areas where high strength and resistance to rotation are crucial, such as securing components like engine covers and underbody panels. Their capability to resist loosening under vibration makes them a preferred choice for critical assembly points.

Tips: When selecting mushroom head bolts for automotive applications, ensure to choose the appropriate material and coating to prevent corrosion, particularly in environments exposed to moisture and chemicals. Using a torque wrench during installation can also help achieve the correct fastening tension, enhancing the integrity and safety of the assembly.

In machinery design, mushroom head bolts contribute to the overall efficiency and longevity of the equipment. They facilitate quick assembly and disassembly, which is vital during maintenance and repair processes. The bolted connections made with these fasteners can also withstand high temperatures and pressures, making them suitable for heavy machinery and industrial applications. Additionally, their aesthetic appeal can provide a polished look to visible components, merging functionality with design elegance.

Tips: Always consult the specific application requirements, including load ratings and environmental factors, to ensure the chosen mushroom head bolts meet the operational demands and safety standards of your machinery design.

Mushroom head bolts are essential fasteners characterized by their unique mushroom-shaped heads, offering a variety of benefits that enhance their applications in different industries. The industry standards for mushroom head bolts are critical in ensuring their reliability and performance. These standards, which often adhere to specifications established by organizations such as ASTM and ISO, set requirements for materials, dimensions, and tensile strength, ensuring that the bolts can withstand the specific stresses and environmental conditions they will face.

When selecting mushroom head bolts, manufacturers must consider several key specifications. The diameter of the head, the length of the bolt, and the type of threading are all crucial factors that dictate the suitability of a bolt for a particular application. Additionally, the material used, commonly carbon steel or stainless steel, plays a significant role in the bolt's corrosion resistance and overall durability. Compliance with industry standards not only enhances safety but also ensures compatibility with other fasteners and the integrity of the assemblies they are part of, making adherence to these specifications vital in engineering and construction projects.

When comparing mushroom head bolts to traditional fasteners, one of the key advantages lies in their unique head design, which allows for effective load distribution. According to a study by the Industrial Fasteners Institute, mushroom head bolts, with their larger surface areas, are capable of bearing higher loads without compromising the integrity of the materials they are fastening. This feature makes them particularly suitable for applications in high-stress environments such as automotive manufacturing and construction, where safety and reliability are paramount.

In addition to load distribution, mushroom head bolts provide ease of installation and removal. Unlike traditional fasteners that might require tools for tightening or loosening, mushroom head bolts can often be operated with minimal equipment thanks to their design. The Fastener Technology International report suggests that the reduced installation time can lead to significant cost savings in labor, especially in large-scale projects. This combination of efficiency and effectiveness positions mushroom head bolts as a superior choice for many industrial applications, particularly where quick assembly and disassembly are needed.

| Mushroom Head Bolt Type | Material | Corrosion Resistance | Load Capacity (lbs) | Applications |

|---|---|---|---|---|

| Standard Mushroom Head | Steel | Medium | 1,200 | Furniture Assembly |

| Stainless Steel Mushroom Head | Stainless Steel | High | 1,500 | Outdoor Applications |

| Aluminum Mushroom Head | Aluminum | Low | 800 | Lightweight Structures |

| Coated Mushroom Head | Carbon Steel | Medium | 1,000 | General Purpose |

| Forged Mushroom Head | Forged Steel | High | 2,000 | Heavy Machinery |

| Brass Mushroom Head | Brass | High | 1,000 | Decorative Applications |

| Plastic Mushroom Head | Plastic | Low | 500 | Electronics |

| Heavy-Duty Mushroom Head | High Carbon Steel | Medium | 3,000 | Construction |

| Galvanized Mushroom Head | Galvanized Steel | High | 1,200 | Marine Applications |

| Metric Mushroom Head | Metric Steel | Medium | 900 | International Standards |