Inquiry

Form loading...

Pipeline fasteners play a critical role in various industrial applications. These essential components ensure the structural integrity of pipeline systems. They come in many forms, including bolts, nuts, and clamps. Without reliable pipeline fasteners, leaks and system failures could occur.

Understanding how pipeline fasteners work is vital for engineers. They create strong connections between pipes, preventing movement and failure. The effectiveness of these fasteners varies with materials and environmental conditions. In some cases, corrosion can undermine their performance. Choosing the right type is not always straightforward.

Engineers often face challenges in selecting fasteners. The environment can complicate decisions. Some fasteners may not perform well under high pressures. Others might not be suitable for extreme temperatures. This complexity requires careful planning and consideration. Awareness of potential failures is crucial for system reliability.

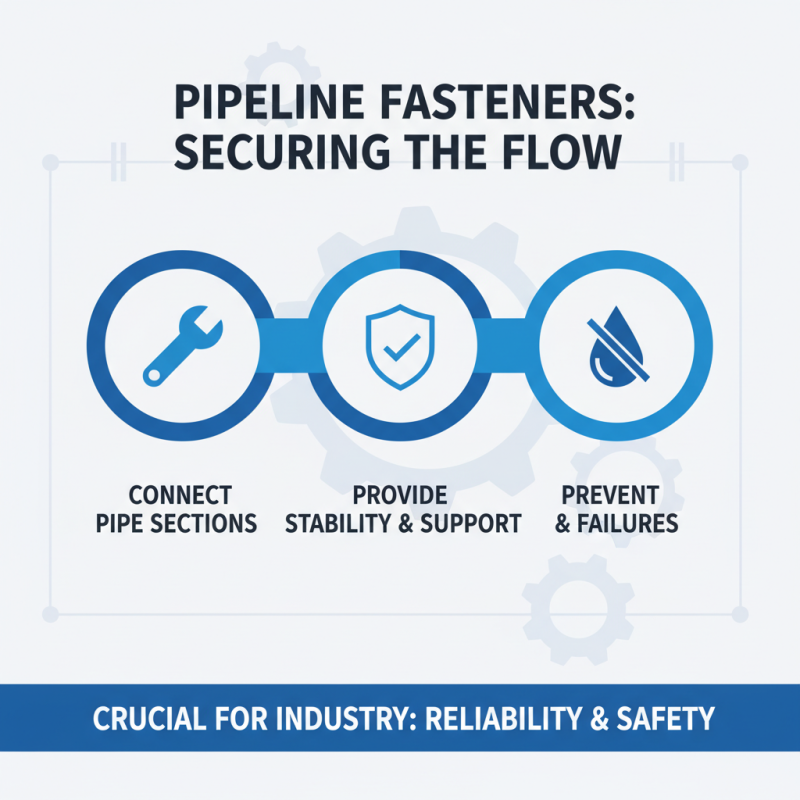

Pipeline fasteners play a crucial role in various industries, ensuring that pipelines remain secure and functional. They are designed to connect different sections of pipe, providing stability and support. This prevents leaks and failures that could lead to costly downtimes or environmental hazards.

There are several types of pipeline fasteners, including bolts, screws, and clamps. Bolts can vary in size and material, often made of steel or other alloys. They provide strong connections but require proper torque during installation. Clamps, on the other hand, can be more user-friendly. They offer easy installation, yet their effectiveness can depend on the surface they grip.

Reflecting on this, one might wonder about the importance of choosing the right fastener. Not all fasteners suit every situation. For example, a heavy-duty application may necessitate a more robust solution. Conversely, lightweight tasks might not need such strength. Thus, understanding the specific requirements of your project can help avoid mishaps down the line.

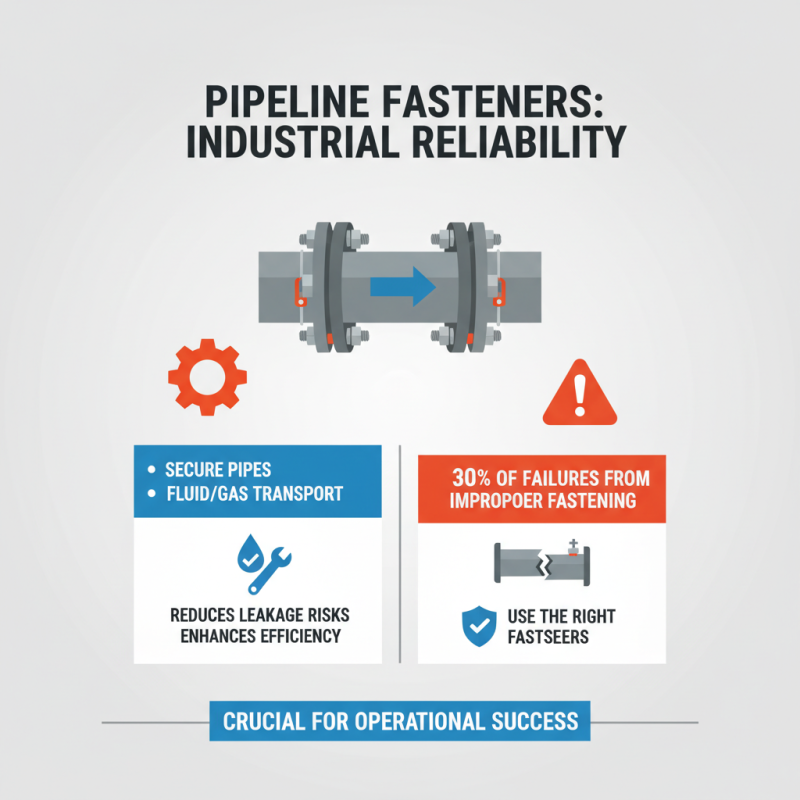

Pipeline fasteners play a crucial role in industrial applications. They secure pipes, ensuring a reliable transport of fluids and gases. Proper fastening reduces leakage risks, enhancing operational efficiency. According to a recent industry report, nearly 30% of pipeline failures stem from improper fastening techniques. This highlights the importance of using the right fasteners in pipeline systems.

Many industries depend on sturdy pipeline fasteners. They are essential in oil and gas, chemical processing, and water supply sectors. A survey revealed that 70% of maintenance teams prioritize regular inspections of fastening systems. This diligence can prevent costly downtime and maintain safety standards. Using the correct materials and designs is vital for long-term performance. Some companies still overlook these critical details, leading to potential hazards.

Tips: Always choose fasteners that comply with industry standards. Regular inspections can identify weaknesses early. Educate teams on fastening best practices. Ignoring these aspects can lead to severe consequences, both financially and operationally.

Pipeline fasteners play a crucial role in various industries. They secure pipes, ensuring stability and preventing leaks. Their design can vary, but they are generally constructed from durable materials. This guarantees longevity under high pressure and temperature conditions.

Understanding how these fasteners function involves looking at their mechanisms. Many fasteners rely on clamping forces to hold pipes tightly together. This pressure creates a seal, minimizing the risk of leaks. The tension in the fasteners must be just right. Too tight, and the pipe could crack; too loose, and it may not hold at all.

Installation can be tricky. Misalignment can lead to failure, affecting safety and performance. Regular inspections are necessary to catch any wear and tear. It’s essential to reflect on the choice of materials and designs. Not all fasteners work best for every application. The right selection sometimes requires trial and error.

When discussing pipeline fasteners, the materials used play a crucial role in determining their performance. Fasteners must withstand pressure, temperature changes, and potential corrosion. Common materials include stainless steel, carbon steel, and alloy steel. These materials are chosen for their unique properties. For instance, stainless steel offers excellent resistance to rust. According to industry reports, stainless steel fasteners can last three to five times longer than their carbon steel counterparts in corrosive environments.

Durability is paramount for pipeline systems. The American Society for Testing and Materials (ASTM) provides guidelines on material specifications. Fasteners made with high-strength steel can endure extreme conditions. They often undergo stringent testing, including tensile strength assessments, which measure their ability to withstand pulling forces. Fasteners of this nature can achieve tensile strengths exceeding 1000 MPa. Yet, not all fasteners meet these standards, which leads to failures that can have serious implications.

Understanding the impact of material choices is essential. Fasteners need to not only fit perfectly but also resist environmental factors. Regular inspections reveal that many systems suffer from premature wear. This can often be traced back to the use of subpar materials. Professionals must prioritize quality to ensure longevity and safety in pipeline infrastructure.

| Fastener Type | Material | Strength (MPa) | Corrosion Resistance | Temperature Resistance (°C) |

|---|---|---|---|---|

| Bolts | Stainless Steel | 520 | High | 300 |

| Nuts | Carbon Steel | 480 | Moderate | 250 |

| Washers | Aluminium | 310 | Low | 200 |

| Clamps | Plastic Composite | 250 | High | 120 |

| Rivets | Copper | 400 | Moderate | 180 |

Proper installation and maintenance of

pipeline fasteners is crucial. These components secure pipes in place, ensuring a reliable flow of materials.

When installing, it's essential to use the

correct tools. Over-tightening can damage the fasteners. Under-tightening can lead to leaks. A close inspection

before installation can reveal any defects.

Regular maintenance is equally important.

Check for corrosion and wear regularly. Replace any fasteners that show signs of damage. An old

fastener may seem fine but could fail unexpectedly. This can lead to spills or accidents. Clear communication with the maintenance team helps in identifying trouble spots.

There are often overlooked areas that need attention.

Documentation of maintenance activities is vital. This practice helps track the condition of fasteners over

time. It could be beneficial to review past incidents. Understanding them can prompt improvements.

Ultimately, attention to detail matters. Small

mistakes can lead to bigger problems later.