Inquiry

Form loading...

In the construction industry, understanding the basics of sleeve anchors is crucial. Sleeve anchors are versatile fasteners, used for securing items to concrete or masonry. According to industry expert John Smith, "Sleeve anchors provide reliable strength for various applications." This statement highlights their importance in construction.

When installed correctly, sleeve anchors create a strong hold. They expand within the base material, offering substantial resistance. Common uses include attaching fixtures like shelves or barriers to walls. However, improper installation can lead to failures, which is a concern for many professionals.

Several factors affect their performance. These include the type of material, anchor length, and load requirements. It's easy to overlook these details, leading to potential issues. Despite their advantages, sleeve anchors require careful consideration. It's essential to appreciate their limitations and acknowledge the necessity of proper techniques.

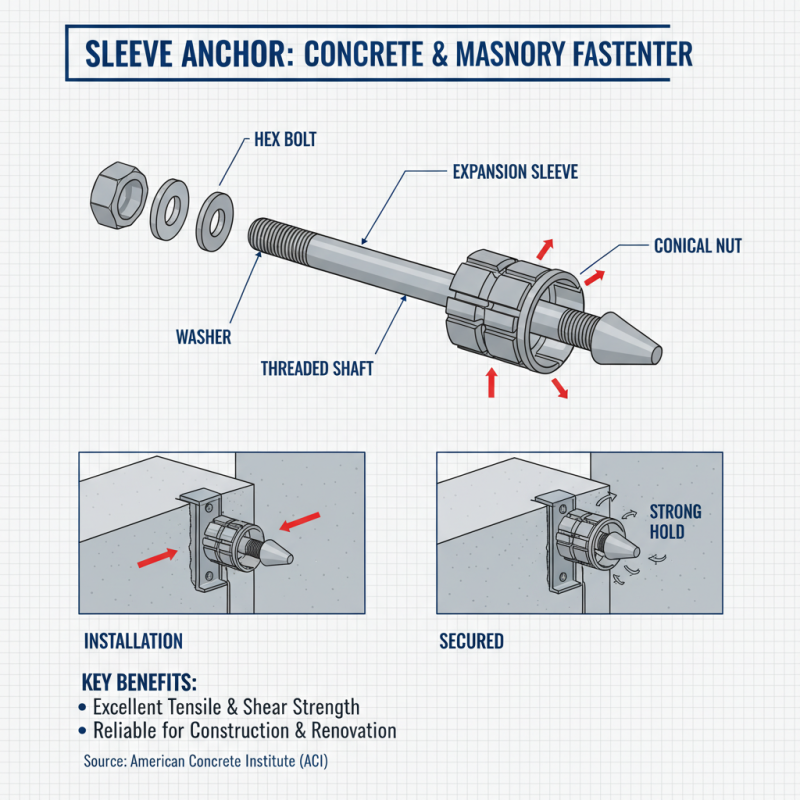

A sleeve anchor is a type of fastener used primarily for securing objects to concrete or masonry surfaces. Its design features a threaded shaft and a sleeve that expands when the anchor is installed. This expansion creates a strong hold within the base material. According to the American Concrete Institute (ACI), sleeve anchors provide excellent tensile strength and shear resistance, making them suitable for various applications in construction and renovation projects.

Installation involves drilling a hole into the concrete and inserting the sleeve anchor. Once the anchor is in place, tightening the bolt causes the sleeve to expand, gripping the surrounding material tightly. This method allows for quick and reliable fixture installation. A report by the Concrete and Masonry Fastener Association suggests that proper installation can enhance the load-bearing capacity by up to 30%. However, improper placement can lead to anchor failure.

It's worth noting that sleeve anchors are not without limitations. They may not perform well in conditions with frequent vibration or shifting. Some experts suggest using alternatives like wedge anchors when dealing with dynamic loads. Additionally, environmental factors can affect their long-term performance. Regular inspection is recommended for installations in high-stress areas.

Sleeve anchors are essential for securing heavy fixtures. They consist of several key components that enhance their functionality. The anchor body is made from durable materials, such as steel or stainless steel. This ensures strength and resistance to corrosion. The sleeve itself is a crucial design feature. It expands when the anchor is tightened, gripping the base material tightly.

The shape of a sleeve anchor can vary. Some have a cylindrical shape while others are more flared at the end. This design aids in distributing stress when loaded. Additionally, the threaded end allows for easy installation and removal. It’s important to consider the correct size for specific applications. A miscalculation may lead to inadequate holding power.

In installation, users must ensure the hole is clean and deep enough. Failure to do so might compromise the anchor's effectiveness. Some anchors may require special drill bits for optimal performance. It’s worth reflecting on the choice of material too. Not all projects require the same grade of anchor. Understanding these components can lead to a more secure attachment in various applications.

Sleeve anchors are essential in fastening applications. They provide strong holding power in concrete, brick, and masonry. Understanding their installation process is crucial for effective use.

To install a sleeve anchor, start by drilling a hole into the base material. Ensure the hole is the correct diameter and depth. It’s easy to mismeasure; re-check before proceeding. After drilling, clean out the debris. A wire brush or compressed air can help here. This step is vital. It prevents weak anchoring.

Next, insert the sleeve anchor into the hole. The anchor should fit snugly. If it’s too loose, it won’t hold effectively. This part is often overlooked. After insertion, use a nut or washer on the anchor. Tighten it with a wrench. Be careful; over-tightening can lead to anchor failure. Ideally, aim for a secure but not excessive tightness. Follow these steps, and you ensure reliable anchoring.

Sleeve anchors are versatile fasteners that are widely used in construction. They provide a strong hold in a variety of materials, including concrete, brick, and masonry. Their unique design includes a sleeve that expands as the anchor is tightened. This expansion helps to create a secure grip, even in challenging conditions.

In construction projects, sleeve anchors are commonly used for installing fixtures like shelving and handrails. They are also essential for mounting heavy equipment or supports. When attached properly, they can significantly increase the safety and durability of structures. However, miscalculations in anchor sizing or installation depth can lead to failure.

Another common application is in securing structural frameworks. Sleeve anchors can connect beams and columns effectively. They serve well in both commercial and residential buildings. But installers must consider local regulations and environmental factors. Not all surfaces will provide adequate support for sleeve anchors. Choosing the right location and anchor type is crucial. Proper planning and assessment can reduce mistakes often made during installation.

Sleeve anchors are essential for securing various fixtures. Their integrity largely comes from adherence to safety standards. Knowing load specifications is crucial for using them effectively.

Generally, sleeve anchors are designed for concrete, brick, or masonry. They provide strong support when installed correctly. Each anchor has a specified load limit. Exceeding these limits can lead to failures. Always consult the manufacturer's guidelines for maximum load capacities.

Tips for installation: Drill the right-sized hole for the anchor. Clean the hole of dust and debris. Improper installation can compromise strength. Use a torque wrench to tighten the anchor. This ensures it is secure without over-torquing.

It is vital to consider environmental factors. Corrosive environments can weaken anchors. Regular inspections are recommended. Look for signs of wear or fatigue—this can indicate potential failures. Don’t overlook these details; they’re critical for safety.