Inquiry

Form loading...

In the construction and engineering sectors, the use of Tie Back Anchorage systems has become increasingly prominent, particularly in projects involving excavation or slope stabilization. According to a recent industry report by the Global Engineering and Construction Market Analysis (2023), the demand for effective anchorage solutions is expected to grow by 15% over the next five years, reflecting the critical role these systems play in enhancing safety and structural integrity. Professionals in the field understand that the right Tie Back Anchorage can significantly influence the success of a project, providing the necessary support to withstand various environmental forces.

Industry expert Dr. Timothy Lawson, a leading engineer known for his extensive research on anchorage systems, emphasizes, "Selecting the appropriate Tie Back Anchorage is not merely a matter of preference but a fundamental decision that impacts the longevity and safety of any construction site." This insight underscores the importance of making informed choices when it comes to Tie Back Anchorage, as the right selection can lead to improved performance and reduced maintenance costs. As project demands evolve, adhering to best practices in tie back anchorage selection becomes essential for engineering professionals seeking to deliver safe and sustainable outcomes.

Tie back anchorage plays a critical role in ensuring the stability and safety of various construction projects. It serves as a means of securing retaining walls, slopes, and excavation sites, allowing for the distribution of forces that might otherwise lead to structural failure. According to a report from the International Society of Soil Mechanics and Geotechnical Engineering, improper tie back anchorage can lead to significant project delays and cost overruns, estimated to be around 15% of the total project budget. This emphasizes the necessity of selecting the right materials and techniques for anchoring systems to maintain site integrity.

Understanding the different types of tie back anchorage and their applications is essential for construction professionals. Factors such as soil conditions, load requirements, and environmental influences must be carefully assessed. The American Society of Civil Engineers highlights that utilizing advanced materials and engineering methods can improve the efficacy of tie back systems. For instance, the use of high-strength steel tendons can enhance the load-bearing capacity significantly. Furthermore, data from the Geotechnical Engineering Report suggests that projects that employ innovative anchorage solutions experience a 20% reduction in maintenance costs over time, showcasing the long-term benefits of informed decision-making in the selection of tie back anchorage methods.

When selecting tie back anchorage systems for your projects, several key factors must be taken into account to ensure both safety and performance. First and foremost, understanding the geological conditions of the site is crucial. Soil type, stability, and groundwater levels can significantly influence the required depth and configuration of the anchorage. According to a recent industry report, improper evaluation of site conditions can lead to system failures, resulting in costly delays and safety hazards.

Another important consideration is the load-bearing capacity of the tie back system. Factors such as the anticipated loads, including both vertical and lateral forces, must be carefully assessed. This ensures that the anchorage can withstand forces exerted during both construction and the lifespan of the structure. Industry estimates suggest that systems designed without adequate load analysis can suffer a failure rate of up to 20%, underscoring the importance of rigorous engineering assessments.

In addition to performance considerations, ease of installation should also be prioritized. Systems that allow for quicker assembly not only reduce labor costs but also minimize disruptions to project timelines. Utilizing modular components can simplify the installation process while enhancing the overall efficiency of anchorage systems. Remember, a well-chosen tie back anchorage system can make the difference between a successful project and unforeseen complications.

When selecting a tie back anchorage for your projects, understanding the material options and their respective pros and cons is crucial. Common materials include steel, fiberglass, and synthetic ropes, each presenting unique characteristics that cater to different project requirements. Steel, known for its high tensile strength and durability, is an excellent choice for heavy-duty applications. However, it can be susceptible to corrosion and may require additional protective coatings to enhance longevity.

Fiberglass, on the other hand, is lightweight and resistant to corrosion, making it suitable for projects in harsh environments. Its dielectric properties are advantageous in electrical applications, yet it may not provide the same strength as steel under extreme loads. Synthetic materials, such as nylon or polyester, offer flexibility and are often easier to handle, but they can be affected by UV exposure and may have limited lifespan compared to metal counterparts. Ultimately, the choice of material should align with the specific demands of the project and the environmental conditions it will face, ensuring optimal performance and safety.

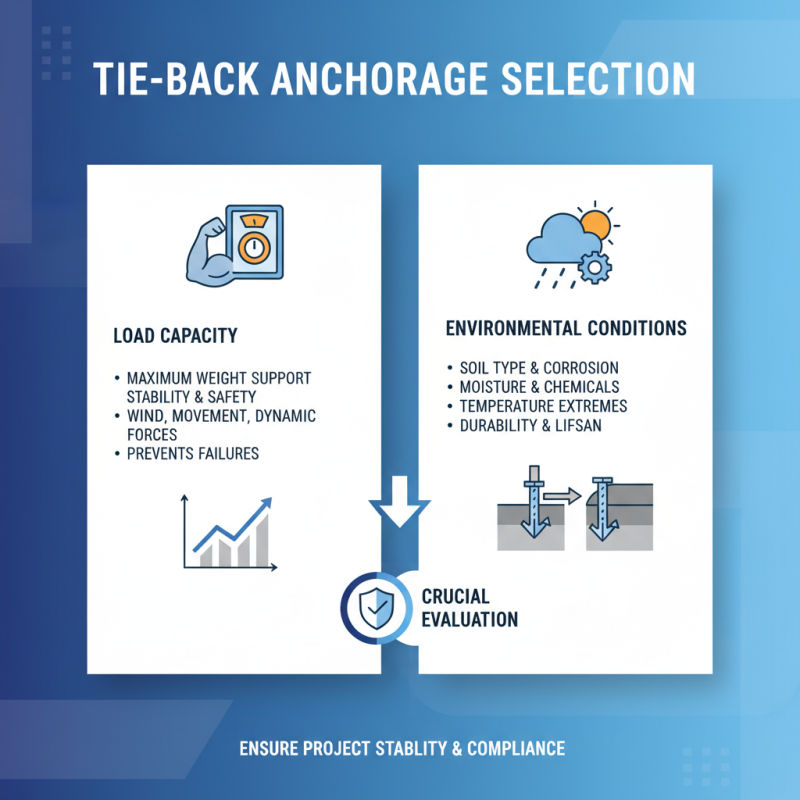

When selecting the best tie back anchorage for your projects, evaluating load capacity and environmental conditions is crucial. Load capacity refers to the maximum weight the anchorage can safely support, which directly affects the stability and safety of your structure. Understanding the specific loads that will be applied during operation, such as wind, structural movement, and dynamic forces, helps in determining the appropriate anchorage type. Conducting a thorough analysis of these loads not only ensures compliance with safety regulations but also assists in preventing structural failures over time.

Environmental conditions significantly influence the performance of tie back anchorages. Factors such as soil type, moisture levels, temperature variations, and exposure to corrosive elements can affect the integrity of the anchorage over time. For instance, in regions with high moisture or corrosive soils, it's essential to choose materials that resist degradation and ensure that the installation method accounts for these environmental challenges. Additionally, seasonal changes can alter soil behavior, so it’s vital to consider long-term performance and durability when making your selection. By meticulously evaluating both load capacity and environmental conditions, you can ensure that your anchorage system is not only effective but also reliable for the duration of your project.

When it comes to tie back anchorage systems, proper installation and maintenance are crucial for ensuring long-lasting performance. According to the American Society of Civil Engineers, improper installation can lead to a 30% reduction in the effective lifespan of anchorage systems, highlighting the importance of adhering to installation best practices. To achieve optimal results, ensure that the anchors are installed at the correct angle and depth, and use the appropriate tools for securing the tie backs. This precision not only enhances the stability of the structure but also mitigates potential risks associated with structural failure.

Maintenance is another critical aspect to consider in the longevity of tie back anchorage systems. A report from the International Association of Foundation Drilling emphasizes that regular inspections should be conducted at least every six months. During these inspections, check for signs of corrosion, displacement, or wear on the components. Additionally, addressing any issues promptly can prevent minor problems from escalating into significant structural failures. Research indicates that a proactive maintenance strategy can extend the functional life of tie back systems by up to 40%, underscoring the importance of routine care in preserving safety and performance.

This chart illustrates the importance of various factors to consider when choosing the best tie back anchorage for your projects. Each factor is rated on a scale from 1 to 10, reflecting how critical they are to ensure long-lasting performance and reliability.