Inquiry

Form loading...

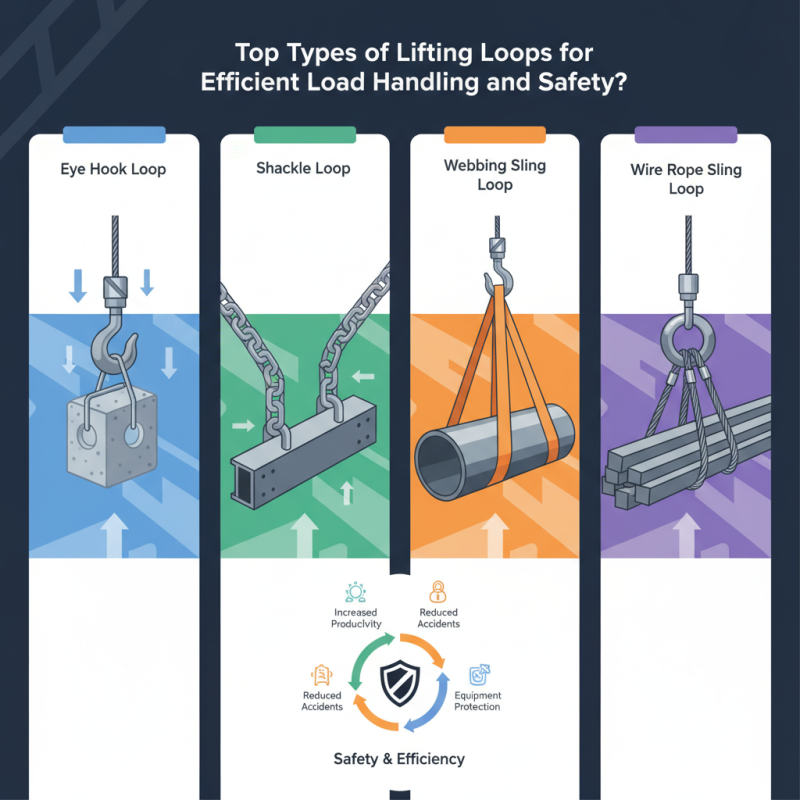

Lifting Loops are essential for safe and efficient load handling in various industries. These loops come in different designs, tailored for specific lifting needs. They enhance the strength and stability of loads during transport, ensuring worker safety.

Efficiency in load handling directly affects productivity. Choosing the right Lifting Loops can reduce the risk of accidents and equipment damage. However, many overlook the importance of selecting appropriate loops. This can lead to safety hazards and operational inefficiencies.

Understanding the various types of Lifting Loops is crucial. Each type serves a distinct purpose and application. Failing to match the loop to the load can create issues. Awareness and knowledge are key to improving safety and efficiency in lifting operations.

When handling heavy loads, lifting loops are essential for ensuring safety and efficiency. Lifting loops, made from strong materials, provide versatile solutions for various lifting tasks. According to industry reports, improper lifting techniques caused over 36% of workplace injuries in the last year. Choosing the right lifting loop can drastically reduce these incidents.

One commonly used type is the eye loop. It allows for quick attachment to hooks or slings, enhancing speed in operations. However, not all eye loops are created equal. Using an inappropriate size can lead to slippage. For instance, if the loop is too large, it can detach under pressure. This highlights the importance of selecting loops with precise specifications.

**Tips:** Always inspect your lifting loops before use. Look for signs of wear, fraying, or degradation. Regular maintenance is crucial.

Similarly, another effective design is the long loop, which provides additional flexibility in movement. It distributes the load more evenly, minimizing stress on any single point. But here lies a common mistake — operators might overlook the weight limitations. Each loop has a capacity limit that must not be exceeded. Failure to comply can lead to catastrophic failures.

**Tip:** Always refer to the manufacturer's guidelines regarding load capacities. Even minor deviations can have serious consequences.

This chart illustrates the effectiveness of various types of lifting loops commonly used in load handling. Each type of lifting loop has distinct characteristics that enhance safety and efficiency in lifting operations.

Lifting loops play a crucial role in various industries. Their importance is evident in construction, manufacturing, and logistics. These loops ensure safe and efficient load handling. They come in various materials and designs. Some are designed for heavy loads, while others are for lighter applications. Understanding the type of loop required is essential.

Tips for choosing lifting loops: Always assess the load capacity. Ensure loops are compatible with your equipment. Inspect them regularly for wear. Picking the right loop can prevent accidents and injuries.

Effective applications of lifting loops vary. In construction, they assist in hoisting materials like steel beams or concrete blocks. In manufacturing, they move components along assembly lines. However, without proper training, workers risk misuse. This reflection can highlight the need for ongoing education on safety standards.

| Lifting Loop Type | Material | Load Capacity (Tons) | Application Areas | Safety Features |

|---|---|---|---|---|

| Eye Slings | Polyester | 5 | Construction, Warehousing | High visibility, reinforced stitching |

| Webbing Slings | Nylon | 10 | Manufacturing, Heavy Machinery | Color-coded load markings, abrasion-resistant |

| Round Slings | Polyester | 15 | Shipping, Oil & Gas | Flexible, lightweight design |

| Chain Slings | Steel | 20 | Construction, Mining | High strength, heat-treated |

| Synthetic Rope Slings | Polypropylene | 8 | Marine, Aerospace | UV resistant, lightweight |

Lifting loops are vital for safe load handling. The choice of materials impacts both strength and weight. Common materials include nylon, polyester, and steel. Each has unique properties. For instance, nylon is flexible but may stretch under heavy loads. Polyester is more rigid, providing better stability. Steel offers immense strength but adds weight.

When choosing lifting loops, consider specific applications. In construction, lightweight materials may improve maneuverability. However, for heavy machinery, strength becomes a priority. Balancing weight and strength is crucial. Some professionals overlook the importance of this balance. They might choose a stronger material without assessing the overall load dynamics.

Inspection is equally important. Regular checks can reveal wear and tear. Some users dismiss minor signs, thinking they won’t impact safety. However, a frayed loop can fail under pressure. Understanding materials and their limitations is essential for safety. Each choice should reflect both current needs and potential risks.

When considering lifting loops, understanding load ratings and safety factors is essential. Industry standards like ASME B30.9 and ISO 13731 provide guidelines for calculating effective load ratings. The load rating depends on various factors, including material type and construction method. For example, synthetic lifting loops generally have load ratings significantly influenced by the orientation and angle of loading.

It's crucial to select lifting loops that match the intended load. Data shows that misused or improperly rated loops can lead to accidents. In fact, up to 30% of lifting accidents are linked to equipment failure. Always check the manufacturer's specifications before use. Pay attention to the maximum load limits. Regular audits of lifting equipment can help maintain high safety standards.

Tip: Inspect your lifting loops frequently for signs of wear and tear. Damaged loops should be replaced immediately. Accurate record-keeping on load ratings and safety factors can improve safety protocols. Mistakes can happen when information is vague, so clarity is essential. Always educate your team on proper lifting practices to reduce the risk of errors.

When it comes to lifting loops, choosing between fixed and adjustable types can be challenging.

Fixed lifting loops are designed for specific load sizes and weights. They offer stability and are less prone to failure.

Use them for consistent loads where precision is key. However, they can’t adapt to different loads easily.

If your load sizes vary, fixed loops may not be the best choice.

Adjustable lifting loops provide flexibility. They can accommodate various load sizes and shapes. This adaptability is ideal for dynamic environments.

However, they require proper adjustment and inspection. An incorrectly set adjustable loop may compromise safety. Always ensure that they are tightened correctly before use.

Tips:

Always check the load capacity before lifting.

Inspect your loops regularly for wear and tear.

Adjust the lifting loop according to the specific load to ensure safety.

Efficiency and safety go hand in hand.

Ignoring safety measures can lead to accidents.

Every lifting operation demands careful consideration.

Lifting loops are essential components in various industries, designed for efficient load handling while ensuring safety during operations. These loops come in different types, each suited for specific applications, which highlights their importance across multiple sectors. Understanding the key materials used in the construction of lifting loops is crucial, as it involves balancing strength and weight to maintain safety standards.

The article also emphasizes the significance of load ratings and safety factors, providing a comprehensive overview of industry standards that govern their use. It draws comparisons between fixed and adjustable lifting loops, outlining scenarios that dictate the use of each type. Finally, best practices for inspecting and maintaining lifting loops are discussed to ensure their longevity and reliability, reinforcing safety measures in lifting operations.