Inquiry

Form loading...

U Bolts are essential fasteners found in various industries. They are shaped like the letter "U" and have threads on both ends. This design allows them to secure items firmly and effectively. U Bolts are commonly used in automotive applications, construction, and plumbing. They can hold pipes, beams, and other structures in place.

The versatility of U Bolts is impressive. They can be used in different sizes and materials, depending on the project needs. For example, larger U Bolts are frequently seen in heavy machinery. However, even with their widespread use, many still overlook their importance. This raises questions about the awareness and understanding of fasteners in general.

Using U Bolts effectively requires attention to detail. Proper sizing and installation are crucial for safety and durability. Yet, some may neglect these factors, leading to potential issues. It’s essential to reflect on these practices. Understanding U Bolts can improve project outcomes and ensure structural integrity.

U bolts are unique fasteners shaped like the letter "U." They typically consist of a curved section with two parallel legs. These legs allow for secure attachment to a variety of materials. This design makes U bolts ideal for mounting pipes, tubing, and other round objects. They are commonly used in construction, automotive applications, and general repair work.

When choosing a U bolt, consider the material it is made from. Stainless steel offers durability and rust resistance, while galvanized steel is more affordable and suitable for outdoor use. Make sure the diameter and length fit your specific needs. If measurements are off, the U bolt may not perform well.

Tips: Always double-check your measurements before purchasing. A small error can lead to big problems down the line. Use washers and nuts to ensure a tight fit. This prevents wobbling and guarantees stability. Remember, not all applications require the same strength. Evaluate your project to avoid over-engineering your solution.

U bolts are essential components in many engineering applications, known for their simple yet effective design. Structurally, they consist of a straight shank bent into a U-shape with threaded ends for securing. Their design allows them to grip pipes, rods, or other cylindrical objects firmly, making them indispensable in construction and automotive industries. According to a recent industry report, over 60% of structural applications utilize U bolts due to their durability and ease of installation.

The material choice for U bolts significantly influences their performance. Steel is popular for its strength, but corrosion resistance can be a concern. Some applications may require stainless steel or galvanized options to enhance longevity. However, adapting U bolts to specific environmental conditions is often overlooked. For instance, in coastal areas, standard steel bolts may rust quickly, reducing reliability. Research indicates that corrosion can reduce U bolt strength by up to 30%, leading to potential failures if not addressed.

Additionally, U bolt dimensions can vary widely, making it crucial to select the correct size for each project. An ill-fitting U bolt may not provide the necessary support, causing an unexpected failure. Engineers must consider factors like load distribution and environmental stresses when choosing U bolts. Improper selection can lead to structural compromise, which highlights the importance of thorough planning and understanding of specific application needs.

| Feature | Description | Common Materials | Applications |

|---|---|---|---|

| Shape | U-shaped metal fastener used to secure objects. | Steel, Stainless Steel, Aluminum | Automotive, Construction, Pipeline Support |

| Design | Consists of a curved section and two legs for fastening. | Carbon Steel, Galvanized Steel | Hangers, Mounts, Clamps |

| Sizes | Available in various diameters and lengths. | Custom and Standard Sizes | HVAC Systems, Structural Support |

| Installation | Typically secured with bolts or nuts on the ends. | Nuts and Washers | Pipe Supports, Electrical Conduits |

| Advantages | Strong, reliable fastening solutions that accommodate vibration. | Corrosion-resistant options available | Machinery, Automotive, Construction |

U bolts are essential components in many applications. They consist of a shaped metal rod bent into a U shape with threaded ends. The versatility of U bolts makes them popular, but their material choices play a crucial role in their effectiveness.

Common materials for U bolts include stainless steel, carbon steel, and plastic. Stainless steel is often favored for its resistance to corrosion and rust. It’s durable and ideal for outdoor settings. Carbon steel, on the other hand, offers high strength and is commonly used in heavy-duty applications. However, it may require protective coatings to ensure longevity. Although these materials have their advantages, they also pose challenges. For instance, stainless steel can be more expensive. This discrepancy sometimes leads to tough decisions in budgeting.

Plastic U bolts are an alternative for lightweight applications. They resist corrosion but may not withstand heavy loads. The choice of material must align with the specific needs of the project. It can sometimes create confusion and lead to errors. Balancing durability, cost, and application is critical. Understanding these materials helps in making informed decisions and ensures the right fit for the job.

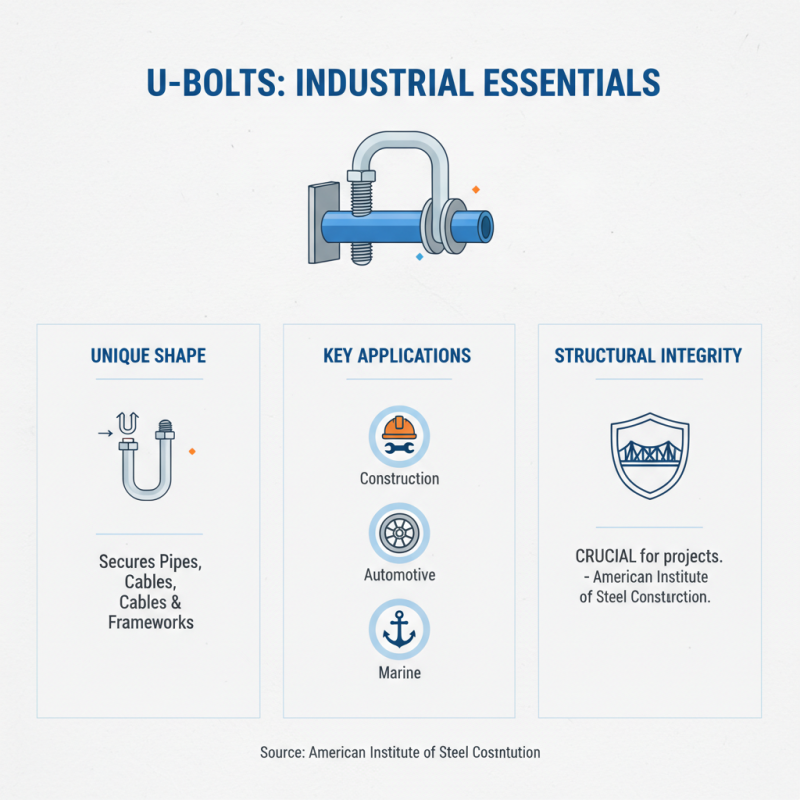

U bolts are essential components across various industries. Their unique shape allows them to secure pipes, cables, and structural frameworks effectively. Common applications include construction, automotive, and marine industries. According to the American Institute of Steel Construction, U bolts are crucial for maintaining structural integrity in many projects.

In the construction sector, U bolts are used to anchor steel beams and support larger structures. These bolts must withstand significant tension and compression forces. A study by the National Institute of Standards and Technology shows that improper installation can lead to structural failure. Therefore, precision is key.

In the automotive field, U bolts frequently secure exhaust systems and suspension components. Their ability to handle vibrations is vital. According to industry experts, using subpar U bolts can result in noise issues and even component damage.

**Tip:** Always choose the right size and grade of U bolt for your application. A common mistake is assuming all U bolts are the same, which can jeopardize performance.

In the marine industry, U bolts help secure rigging and mooring lines. Saltwater corrosion is a concern here. Using stainless steel U bolts can help mitigate this issue, ensuring longevity. However, not all stainless steel is created equal.

**Tip:** Regularly inspect U bolts in marine applications. Signs of corrosion can indicate a need for replacement. Ignoring this can lead to failure at sea, posing serious risks.

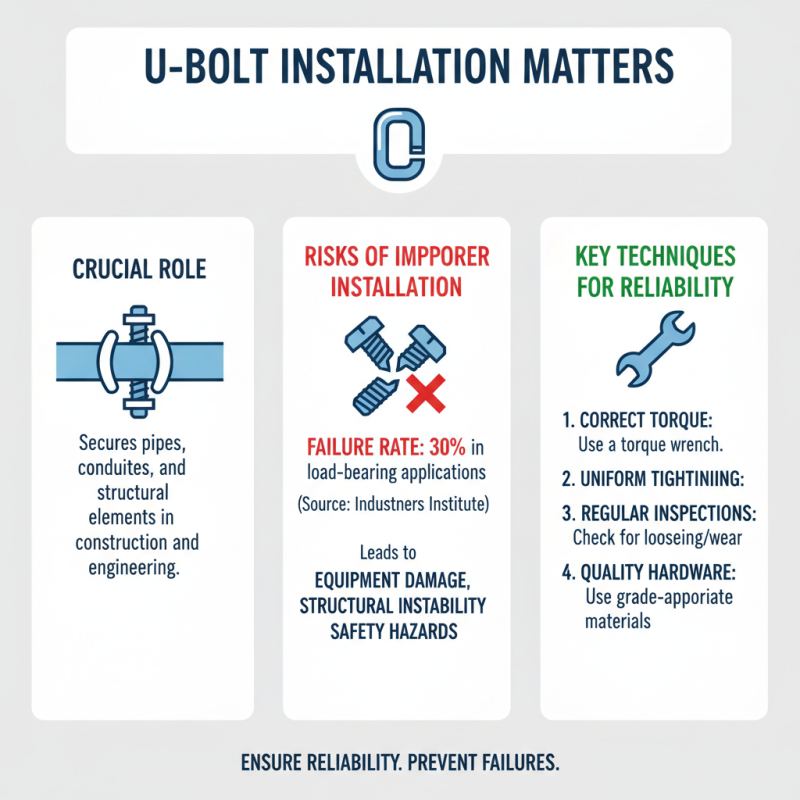

U bolts serve a vital role in many construction and engineering applications. Proper installation techniques are crucial for their effectiveness. According to a report by the Industrial Fasteners Institute, improper installation can lead to a staggering 30% failure rate in load-bearing applications.

When installing U bolts, ensure they are aligned correctly and snugly against the surfaces they secure. Use a torque wrench to achieve the recommended torque specifications. Many experts recommend checking torque levels after initial use. This practice is often overlooked, but even slight shifts can compromise structural integrity.

Best practices include using washers under the nuts. This enhances load distribution and minimizes surface wear. It is also important to regularly inspect U bolts for signs of corrosion or wear. Visual checks can reveal issues before they escalate. Despite following guidelines, human error can occur. Regular training for teams can mitigate this risk and promote consistent performance. Effective installation involves precision, attention to detail, and ongoing evaluation of conditions.