Inquiry

Form loading...

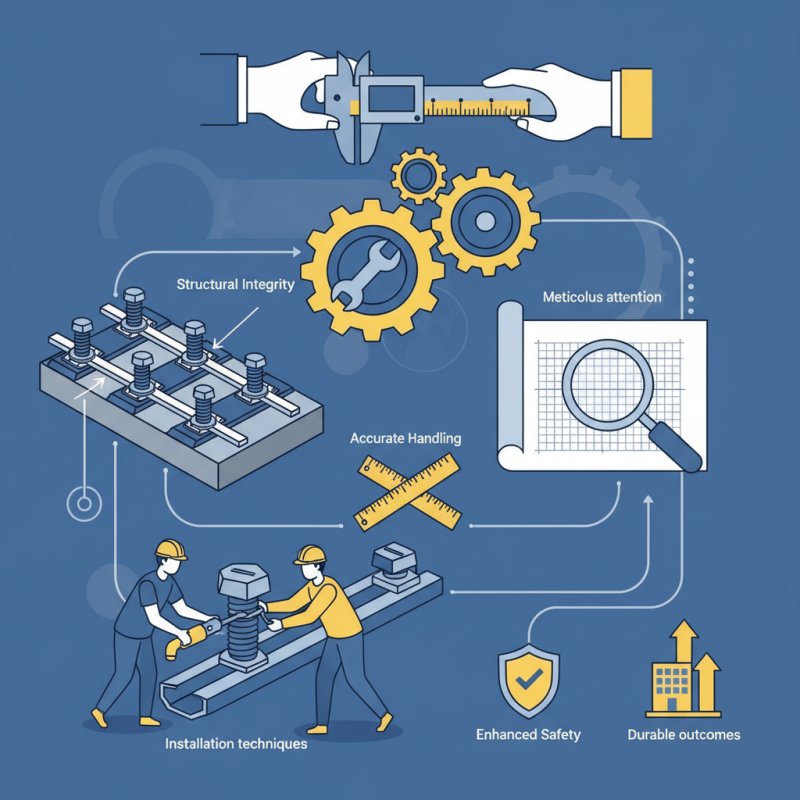

In the world of construction and engineering, precision is paramount, and one crucial component that often goes unnoticed is the track bolt. As integral fixtures that secure the structural integrity of various assemblies, track bolts require meticulous attention during both measurement and installation. This guide aims to illuminate the essential tips and best practices that ensure accurate handling of track bolts, thereby enhancing both safety and functionality in your projects.

Understanding the importance of track bolts in maintaining alignment and stability can significantly impact the overall success of an installation. From their selection to installation techniques, mastering the intricacies of track bolts is vital for professionals and DIY enthusiasts alike. With the right knowledge, one can avoid common pitfalls and achieve a flawless setup, ultimately leading to durable and reliable construction outcomes. Whether you are tasked with a large-scale project or a modest repair, these insights into track bolts will serve as a valuable resource in navigating these critical elements with confidence.

Track bolts are essential fastening elements in construction, widely utilized for securing various structural components. There are several types of track bolts, including plain track bolts, flange bolts, and shoulder bolts, each serving distinct applications. Plain track bolts, with their non-threaded shank, provide robust fastening for connecting two surfaces in applications like metal framing. Flange bolts, featuring a wider bearing surface, are ideal for construction scenarios where load distribution is critical, such as in heavy machinery assemblies. Shoulder bolts, designed with a cylindrical shoulder, facilitate rotation and are often used in applications requiring pivot points.

When installing track bolts, ensuring accurate measurement is crucial for structural integrity. One essential tip is to double-check the alignment of your bolt holes before drilling. Misalignment can compromise the assembly's strength, leading to potential failures. Additionally, using a torque wrench during installation can guarantee that each bolt is tightened to the manufacturer's specifications, preventing over-tightening that may damage the materials or the bolt itself.

Furthermore, consider the materials of both the track bolt and the surfaces they will join. Using compatible materials can prevent corrosion and ensure longevity. For improved performance, lubricate the threads to reduce friction during tightening, which will make it easier to achieve the desired torque. By following these tips, you can ensure a more efficient and effective installation process for track bolts in your construction projects.

When it comes to measuring track bolts accurately, having the right tools and equipment is essential for ensuring the integrity of any construction or engineering project. Precision measurement tools such as calipers, micrometers, and torque wrenches play a vital role in obtaining accurate dimensions and ensuring proper installation of track bolts. According to industry reports, using calibrated measurement tools can reduce the margin of error to less than 1%, which is crucial in high-stakes applications such as rail systems and structural frameworks.

In addition to hand tools, investing in advanced measuring instruments like digital theodolites and laser measuring devices can enhance accuracy further. These tools allow for quick and precise measurements over larger distances, minimizing human error associated with traditional methods. A study published in the Journal of Construction Engineering and Management highlights that projects utilizing modern measuring technologies can complete phases up to 20% faster while maintaining quality standards. This demonstrates the importance of equipping teams with the necessary tools for accurate measurement and installation of track bolts, ultimately leading to safer and more efficient construction outcomes.

When it comes to installing track bolts, precision is paramount. To achieve accurate measurements, begin by gathering essential tools such as a caliper, a measuring tape, and a level. Start by measuring the diameter of the bolt hole and the length of the bolt you’ll need. It’s important to measure multiple times to ensure consistency; even a slight discrepancy can result in improper installation, leading to safety hazards.

Next, ensuring the correct spacing between bolts is crucial for a secure fit. Use a template or a drawing to mark the locations where each bolt will be installed. Accurately measuring the distance between the marked spots helps maintain uniformity and contributes to the structural integrity of the assembly. Additionally, consider the thickness of the material being fastened and the load it will bear, as these factors can influence the size and number of bolts needed. By carefully following these steps, you can guarantee that your track bolts are measured and installed with the utmost precision, ensuring a robust and safe application.

| Dimension | Measurement Method | Precision Tool | Installation Tip |

|---|---|---|---|

| Diameter | Caliper | Digital Caliper | Ensure the caliper is calibrated. |

| Length | Tape Measure | Metal Tape Measure | Double-check measurements before cutting. |

| Thread Pitch | Thread Gauge | Thread Pitch Gauge | Use proper gauge for accurate pitch identification. |

| Torque Specification | Torque Wrench | Digital Torque Wrench | Follow torque specifications to prevent damage. |

| Material Type | Visual Inspection | N/A | Choose material based on application requirements. |

When installing track bolts, it is essential to follow

best practices to ensure both longevity and safety. Begin by selecting the

appropriate bolt size and type

for your specific application, as this will determine the load-bearing capacity and

overall effectiveness of the installation. Pre-inspect the surfaces to ensure they are

clean and free of debris, as any contaminants can compromise the integrity of the connection.

Additionally, consider using a torque wrench

to apply the manufacturer-recommended torque values, which helps to achieve optimal

tightness without over-stressing the materials involved.

Proper alignment is crucial for the efficacy of track bolt installation. Before

tightening, verify the alignment of the components to avoid undue stress on the bolts,

which can lead to failure over time. Utilize guide holes where necessary, and always

follow a sequential tightening pattern to distribute stress evenly across the assembly.

After installation, perform regular inspections and maintenance checks to monitor for

any signs of wear, corrosion, or loosening, ensuring

that the installation remains secure and functional throughout its lifespan.

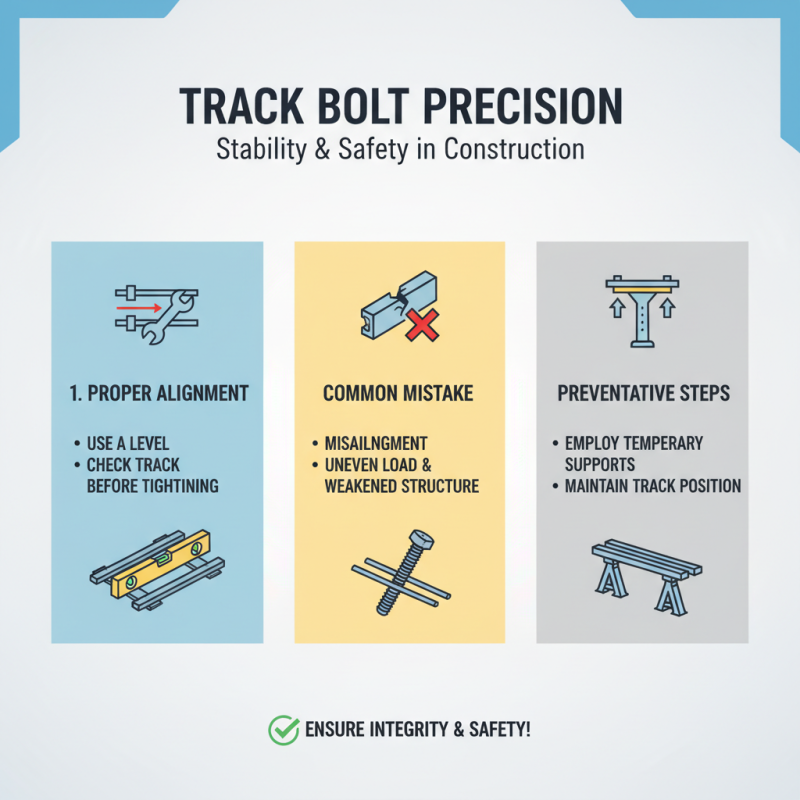

When working with track bolts, precision is essential to ensure stability and safety in any construction project. One common mistake is not properly aligning the bolts during installation. Misalignment can lead to uneven load distribution, compromising the integrity of the structure. To avoid this, always use a level and check the alignment of the track before tightening the bolts. Employing temporary supports can also help maintain the position of the track while you ensure everything is correctly set.

Another frequent error involves using the wrong torque settings when fastening bolts. Over-tightening can stress the bolt or the track, leading to potential failure, while under-tightening may allow for movement that can reduce the connection’s effectiveness. It's crucial to refer to specifications for torque settings and consider using a torque wrench to achieve the correct tightness. Additionally, inspecting bolts for signs of wear and replacing them as necessary can prevent failures related to fatigue or damage that often go unnoticed until it’s too late. By being aware of these common pitfalls and implementing these solutions, you can enhance the accuracy and reliability of your track bolt installations.