Inquiry

Form loading...

When it comes to hardware, the right choices matter. Dome Head Bolts are essential for many projects. They offer a unique combination of strength and design. In 2026, selecting the best Dome Head Bolts requires careful consideration.

These bolts feature a rounded head, which can enhance aesthetics. They are often used in applications where appearance matters. However, their functionality should not be overlooked. Dome Head Bolts can resist wear and corrosion effectively, making them a popular choice for outdoor projects.

Choosing the right material and size can be challenging. Not all Dome Head Bolts will fit every need. Research is key to ensuring they meet your project's demands. It's essential to reflect on your choices, as the wrong bolts can lead to failures and costly repairs.

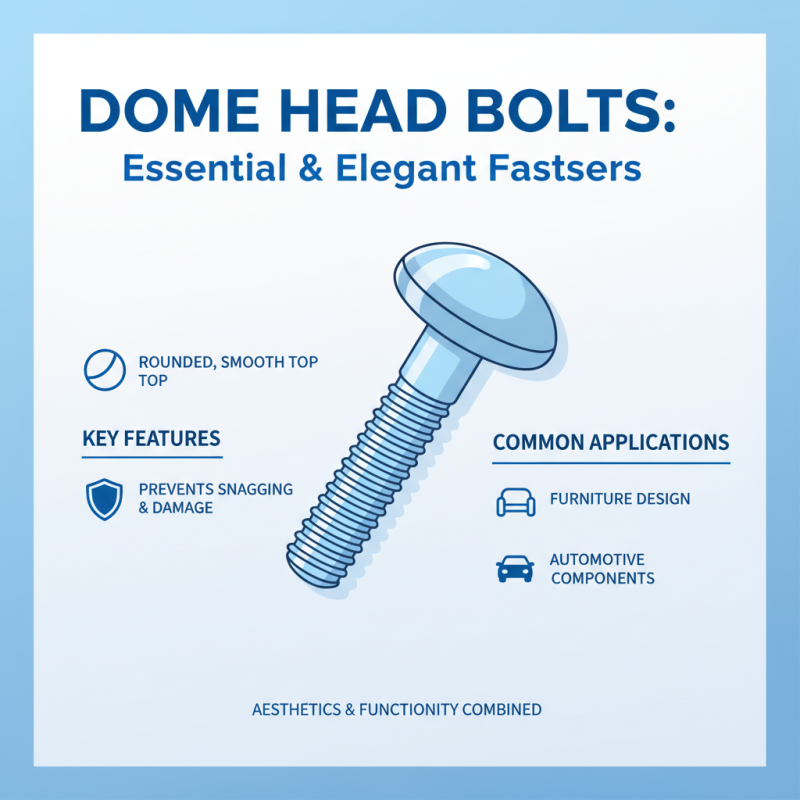

Dome head bolts are essential components in various applications. Their design features include a rounded top that provides a smooth surface. This aspect helps to prevent snagging or damage to surrounding materials. These bolts are typically used in places where aesthetics matter, such as furniture and automotive designs.

The material used in dome head bolts can vary. Many are made from steel, though some use stainless steel or aluminum. The choice influences their strength and resistance to corrosion. Diameter and length can also differ significantly, making it crucial to select the right one for specific tasks. However, individuals often overlook the importance of matching bolt specifications to intended loads.

Using dome head bolts can have advantages. They offer a sleek look and are easier to install. Yet, issues may arise if used improperly. Over-tightening can lead to stripped threads or broken bolts. Understanding these potential pitfalls is vital for anyone looking to use dome head bolts effectively. Choosing the correct type isn't just about appearance; performance matters too.

Dome head bolts come in various materials, each offering unique properties. Steel is a common choice for strength. It's durable and widely used in construction and automotive applications. However, steel can also be prone to rust, requiring protective coatings. Stainless steel offers better corrosion resistance, making it ideal for outdoor projects. Yet, it tends to be more expensive.

Aluminum dome head bolts are lightweight and resistant to corrosion. They’re often used in aerospace and marine applications. However, aluminum may not provide the same strength as steel. This makes it less suitable for high-load situations. Plastic bolts are an option for non-structural applications. They’re often used in electronics and plumbing. While inexpensive, they lack the strength of metal alternatives.

When choosing the right material, consider the environmental factors. Humidity and exposure to chemicals can affect longevity. The specific application is crucial as well. A bolt that works in one setting may fail in another. Evaluating these factors leads to better choices. Understanding the differences aids in making informed decisions.

Dome head bolts are versatile fasteners used across various industries. Their unique shape offers a larger bearing surface, distributing loads effectively. This makes them ideal for construction, automotive, and manufacturing applications. In construction, they secure timber and steel structures, supporting tensile strength. The automotive sector relies on dome head bolts for assembly, ensuring vehicle safety and durability.

According to a 2022 market report, the global fastener industry is projected to reach $120 billion by 2025. With dome head bolts gaining popularity, their application in innovative designs is expected to rise. In manufacturing, these bolts fasten assemblies in machinery, reducing vibration and wear in operations. Their unique attributes make them essential for reliable connections, enhancing product performance.

Tips: Always consider the material of the dome head bolts. Different materials offer distinct strength and corrosion resistance. Proper selection prolongs service life. Regular inspections are necessary. Wear and fatigue can occur over time, leading to failure. Renewing bolts before they show signs of damage is crucial for safety.

| Dimension (mm) | Material | Coating Type | Tensile Strength (MPa) | Application Industry |

|---|---|---|---|---|

| 10 x 50 | Steel | Zinc Plated | 500 | Construction |

| 8 x 25 | Stainless Steel | None | 600 | Automotive |

| 12 x 75 | Aluminum | Anodized | 300 | Aerospace |

| 6 x 20 | Brass | Gold Plated | 450 | Electronics |

| 14 x 100 | Steel | Hot-Dip Galvanized | 700 | Infrastructure |

When selecting dome head bolts, size and specifications are crucial. Dome head bolts come in various lengths and diameters. Choosing the wrong size can lead to installation issues. If the bolt is too long, it may protrude awkwardly. Too short? It might not secure the parts properly. Measure accurately before making a choice.

Material matters, too. Common materials include stainless steel and alloy steel. Each has unique properties. Stainless steel resists rust, while alloy steel is stronger. Think about the environment where you will use the bolts. Outdoor applications need corrosion resistance.

Don't overlook the thread type. Bolts can have coarse or fine threads. Coarse threads grip better in softer materials. Fine threads provide a tighter fit in stronger materials. Reflect on your project requirements before deciding. Sometimes, the specifications can be overwhelming. Ignoring these details often leads to problems later. Taking time to choose correctly saves headaches down the line.

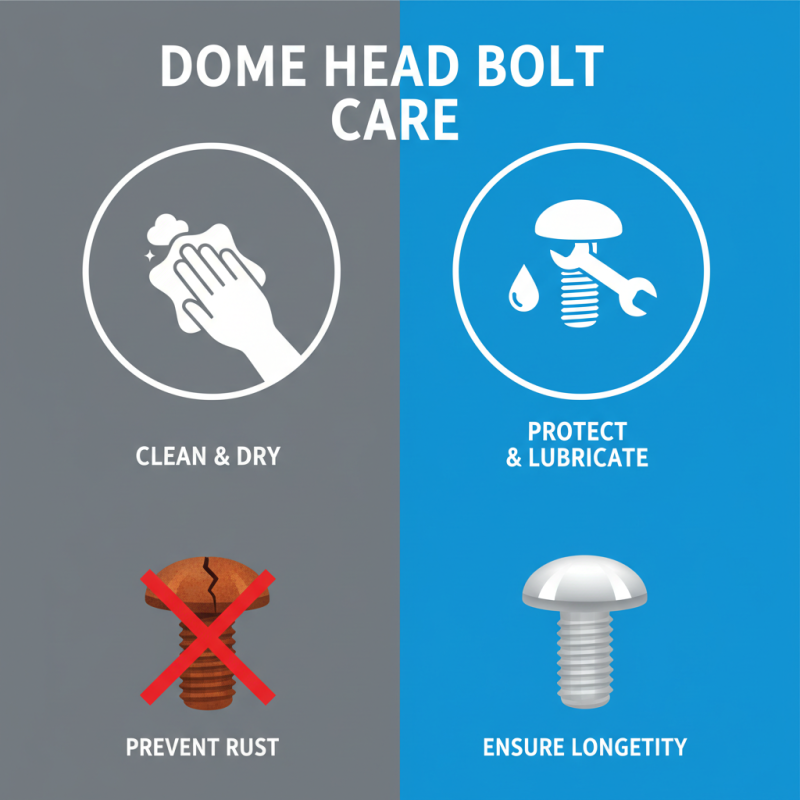

Dome head bolts are known for their strength and versatility. To maintain their longevity, it’s crucial to keep them clean and dry. Dirt or moisture can lead to rust. Regularly wipe them down with a cloth to remove debris. Also, consider applying a protective lubricant to prevent corrosion.

When using dome head bolts, ensure they are not over-tightened. Over-tightening can lead to stripping or breakage. It's essential to use the right tools to achieve the proper torque. Remember, even high-quality bolts can fail if misused.

Check your bolts periodically for wear. Look for signs of fatigue or deformation. If you notice any issues, replace them immediately. A small crack can lead to bigger problems. Simple maintenance can significantly enhance the performance of dome head bolts in any application.