Inquiry

Form loading...

When selecting Hex Bolts for your project, the decision can be daunting. The right choices affect functionality and safety. Industry data indicates that over 70% of construction failures are linked to improper fastener selection. Thus, careful consideration is crucial for project success.

Expert in fasteners, Dr. Emily Thompson, notes, "Choosing the right Hex Bolts is vital, yet often overlooked." Her insights highlight the common oversights in identifying the specific requirements for tension and load. Hex Bolts come in various grades and materials, each affecting performance. Understanding these specifications can lead to improved durability.

A poor choice can lead to catastrophic failures, raising safety concerns. Many overlook the importance of matching the bolt's strength to the intended load. Additionally, environmental factors like corrosion resistance are frequently ignored, leading to premature wear. These elements emphasize the need for reflection on your selections, ensuring the right Hex Bolts for exceptional project outcomes.

When selecting hex bolts, understanding their types and specifications is crucial. Hex bolts come in various grades and materials. Common grades include Grade 2, Grade 5, and Grade 8. Each grade has defined tensile strength and yield strength values. For instance, Grade 5 bolts have a minimum tensile strength of 105,000 psi, while Grade 8 bolts can reach up to 150,000 psi. This data highlights the importance of using the right grade for your specific application.

Beyond grades, material selection can significantly affect bolt performance. Steel is the most common material, but options like stainless steel and alloy steel are also popular. Stainless steel offers excellent corrosion resistance, making it suitable for outdoor applications. However, its higher cost may not be justified in all projects. As an engineer, I sometimes find myself questioning whether to invest in more durable materials or stick with the basics.

Thread specifications also play a vital role. Both coarse and fine threads have distinct applications. Coarse threads offer better grip in softer materials. Fine threads, on the other hand, provide better tension in hard materials. This contrast is often overlooked. Deciding on the thread type should align with the material being fastened. Making the wrong choice can compromise safety. It’s essential to analyze the project specifications and the environment when making this decision.

When starting a project, understanding the load requirements is crucial. Loads can differ, depending on what you are constructing. You may need to think about tension, shear, and even torsional forces. Each of these forces can affect how you select hex bolts.

For instance, a simple bookshelf requires less load-bearing capacity than a heavy-duty shelf for tools. Easy projects might allow for more flexibility in bolt selection. However, complex or heavy-duty projects demand careful calculations. Ignoring these details could lead to structural failure. A bolt that seems adequate may not hold under stress.

Consider the weight your project will bear. Regularly assess whether the bolts are up to par. If unsure, research or consult an expert. Sometimes, the perfect bolt choice is not obvious. It’s essential to be aware of the materials you are joining, as they can also determine load requirements. You may think a common bolt is enough, but that could be a costly mistake in the long run.

When selecting hex bolts, the material choice is crucial.

Common materials include steel, stainless steel, and brass. Each type has distinct properties. For example,

steel is strong but can corrode.

Stainless steel resists rust well, making it ideal for outdoor projects. Brass, while not as strong, offers excellent corrosion resistance. According to industry reports, about

70% of projects fail due to improper material selection.

Choosing the right material can prevent costly failures. Often, people overlook the environment where the bolts will be used. For instance, high humidity or exposure to chemicals can lead to premature failure. Consider the specific needs of your project. Do the bolts need to withstand high temperatures or vibrations? These factors influence material choice significantly.

Tip: Always check the tensile strength and hardness of the materials. This data is vital in ensuring your bolts can handle the pressure they will face. Another point to consider is the finish. A good finish can enhance the longevity of the bolts. However, don’t just rely on looks; assess functionality above all.

Choosing the correct size and length of hex bolts is critical for a successful project. A bolt that is too short may not provide the necessary grip. Conversely, a bolt that is too long can lead to protrusions, which may pose hazards. According to industry standards, the length of a bolt should extend at least 1-2 threads beyond the nut. However, this can vary based on the application and type of materials being fastened.

When selecting the size, consider both the diameter and the length. The diameter needs to fit snugly into the pre-drilled hole. A loose fit can lead to structural failures. In practice, a report from the American Society of Civil Engineers emphasizes that improperly sized bolts are a common cause of assembly issues. It suggests using a caliper for accurate measurements. Many builders overlook this simple step, which can result in costly rework.

Think about the material being bolted as well. Different materials require different bolt sizes. For example, softer materials like wood may not need as large a bolt. In contrast, heavier metals will need more robust, longer bolts. Some contractors often underestimate the importance of this. The wrong size can lead to failures that are both dangerous and expensive. Use caution when making your selection.

| Bolt Size (Diameter) | Length (mm) | Material | Strength Grade | Typical Applications |

|---|---|---|---|---|

| M6 | 20 | Steel | 8.8 | Light machinery, furniture |

| M8 | 30 | Stainless Steel | A2-70 | Automotive parts, construction |

| M10 | 40 | Carbon Steel | 10.9 | Heavy machinery, structural applications |

| M12 | 50 | Alloy Steel | 12.9 | Industrial equipment, heavy load bearing |

| M16 | 60 | Stainless Steel | A4-80 | Marine applications, chemical processing |

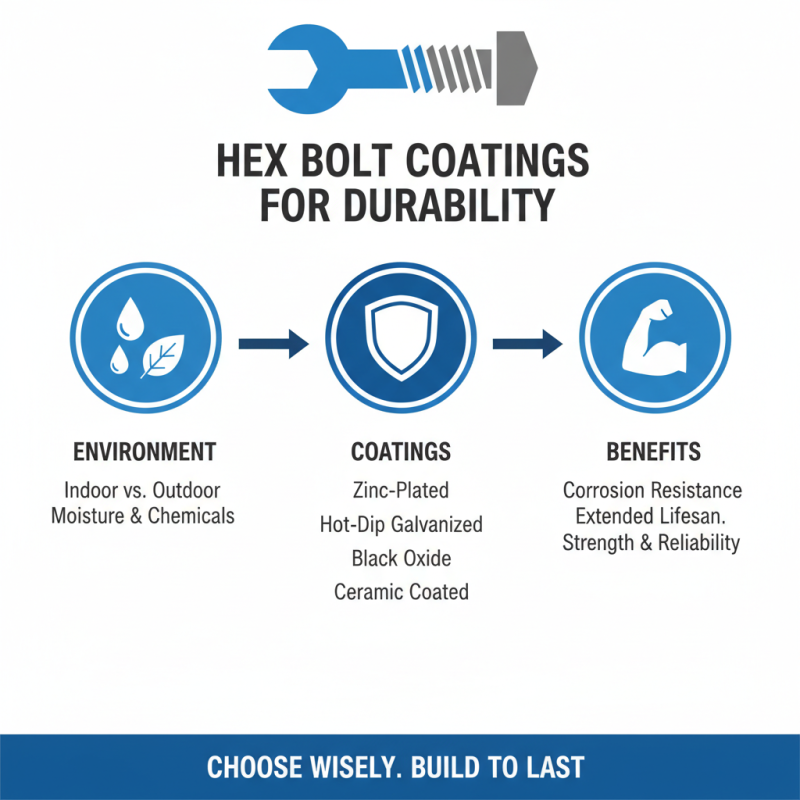

When choosing hex bolts for your project, it’s crucial to consider coatings and finishes that enhance durability. The environment where the bolts will be used greatly impacts the choice. For example, outdoor projects may involve exposure to moisture and chemicals. In such cases, choosing bolts with a corrosion-resistant coating is essential.

Common coatings include zinc plating and anodizing. Zinc-plated bolts offer a shiny appearance and moderate protection against rust. However, they may not last long in harsh conditions. Anodized bolts, on the other hand, provide a thicker, more durable finish. This type can withstand wear better than zinc, but the color may fade over time.

It's important to reflect on the specific conditions of your project. Are the bolts for indoor or outdoor use? Will they be exposed to high levels of humidity? Selecting the right coating requires careful thought. Failing to do so can lead to premature rusting and structural issues. Always weigh the benefits of each coating against the potential drawbacks.