Inquiry

Form loading...

In the construction and civil engineering sectors, selecting the correct Nut Prestressed Anchorage is vital for project success. According to a recent market analysis by ResearchAndMarkets, the global prestressed anchorage market is projected to grow at a CAGR of 5.2% over the next five years. This growth underscores the increasing importance of proper anchorage systems in both new initiatives and infrastructure upgrades.

Experts emphasize the critical factors in this decision-making process. Dr. Michael H. Anderson, a consultant specializing in anchoring systems, notes, “The choice of Nut Prestressed Anchorage can greatly influence the overall stability of any structure.” His insights remind us that the wrong choice can lead to safety risks and structural failures that might have serious consequences.

In practice, many engineers face dilemmas regarding different anchorage systems. There can be confusion around material costs, load capacities, and installation requirements. Some projects may overlook the deadlines due to these complexities. Thus, understanding the specific needs of each project is essential. Careful evaluation of options will enhance the durability of structures built today.

When selecting a nut prestressed anchorage, understanding the various types available is crucial. Two main types dominate the market: bonded and unbonded anchorages. Bonded anchorages often provide superior load transfer because of the adhesive used. They are favored in applications where environmental factors are a concern.

Unbonded anchorages, on the other hand, showcase flexibility. They allow for easier tensioning adjustments. In a 2022 industry report, unbonded systems were shown to reduce installation time by nearly 25%. However, they can be susceptible to corrosion if not properly maintained.

Tips: Always conduct a site assessment to determine environmental factors. This can affect anchorage choice. Also, consult with engineers to evaluate load requirements. Each project has unique needs that must be factored in.

Before committing to a choice, reflect on the long-term implications. Each type has benefits and drawbacks. Understanding these will lead to informed decisions. Sometimes, the best option isn't the most popular one. Proceed cautiously and consider the specific requirements of your project.

This bar chart represents the load capacity of various types of nut prestressed anchorages, allowing you to compare their performance in your project. Each type has different load capacities measured in kilonewtons (kN), which can influence your choice for optimal anchorage selection.

When selecting the right nut prestressed anchorage, evaluating load requirements is crucial. Assess the anticipated loads carefully. Think about vertical, horizontal, and dynamic forces. Each project has unique demands, and overlooking these can lead to failure. Accurate calculations can prevent structural issues later.

Consider the material and environmental conditions of your project. These factors influence the load-bearing capacity of the anchorage. Heavy loads require stronger, more durable materials. Weathering can weaken anchors over time. Evaluate how these elements impact your design decisions. Testing prototypes could reveal weaknesses in your setup.

Sometimes, even the best estimates fall short. Unexpected loads or environmental changes can occur. It’s important to stay adaptable and ready to revise your plan. Regular assessments help keep the project on track. Learning from past experiences is vital. Each project teaches new lessons about load requirements and anchorage selection.

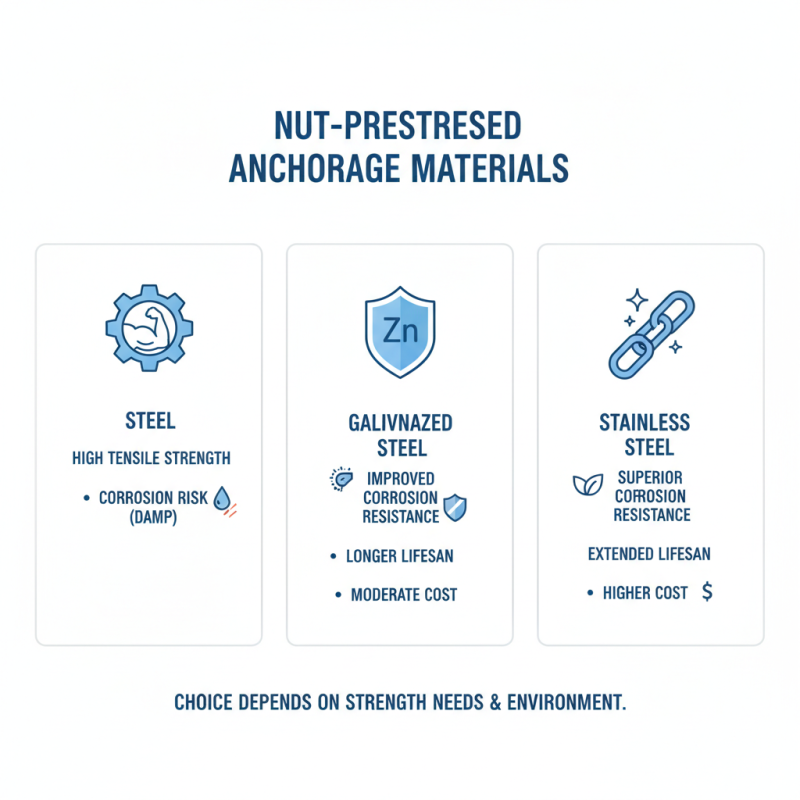

When selecting nut prestressed anchorages, material choice is critical. Different materials offer various strengths and environmental resistances. For instance, steel is commonly used due to its high tensile strength. However, steel can corrode, especially in damp conditions. Using galvanized steel or stainless steel can mitigate corrosion risks. These materials extend the lifespan of the anchorage but may come at a higher cost.

Another option is composite materials. Composites are increasingly popular due to their light weight and resistance to corrosion. They perform well in harsh environments but may lack the strength of steel in heavy load applications. This can be a significant drawback for projects requiring high durability. It’s essential to evaluate your specific needs regarding load capacity and environmental conditions.

Consider the long-term implications of your choice. Are you prioritizing durability, cost, or weight? Each project may require a different approach. Reflecting on past experiences can guide your decision. Often, the best choice balances cost and performance while considering unique project requirements. Stay mindful of trade-offs and ensure the materials align with your project goals.

When considering the installation of nut prestressed anchorages, the methods you choose significantly impact the outcome. Common techniques include tensioning the anchor bolts and using hydraulic jacks. Each method has its intricacies, and it’s essential to pay close attention to details. For instance, the alignment of the anchors must be precise. Misalignment can lead to uneven load distribution.

Selecting the right installation sequence is also crucial. Improper sequencing can lead to unnecessary complications. For example, if you don’t ensure a proper cure time for grouting materials, it can weaken the anchorage. Always remember to double-check your measurements. A small error could have cascading effects on the project.

Ultimately, maintaining a clear communication line among team members can prevent mistakes. Encourage an open dialogue about potential issues. Regularly review the installation process and be willing to adapt. Every project presents unique challenges, and acknowledging this is key. A reflective mindset can foster improvement in future installations.

| Dimension | Description | Best Use Case | Installation Method | Considerations |

|---|---|---|---|---|

| M20 | Medium size nut anchorage | Residential Buildings | Manual Installation | Ensure proper torque application |

| M30 | Large nut anchorage | Commercial Structures | Hydraulic Torque Wrench | Requires precise calibration |

| M16 | Small size nut anchorage | Lightweight Structures | Impact Wrench | Check for stress limits |

| M24 | Versatile medium anchorage | Bridges and Overpasses | Torque and Tension Control | Monitor tension during installation |

| M12 | Compact anchorage option | Precast Elements | Manual Wrench | Sufficient preload required |

When budgeting for nut prestressed anchorages, consider initial costs versus long-term benefits. According to industry reports, materials typically account for 40% of total anchorage costs. This emphasizes the need to select high-quality components that could enhance durability and reduce future repairs. In practice, the upfront costs may seem higher. However, investing in reliable materials can offset costs through longevity and lower maintenance requirements.

Another crucial aspect is installation expenses. Skilled labor can contribute significantly, sometimes up to 30% of the total project budget. Choosing a reliable contractor is essential, yet this can lead to concerns about price versus quality. A lower bid may attract attention, but it might compromise overall safety. Inaccurate installation can lead to catastrophic failures.

Finally, examine the lifecycle costs of different anchorage types. A 2022 study highlights that low-quality anchorages could lead to costs exceeding 150% of the initial investment over time. It’s vital to conduct a thorough analysis before making decisions. Balancing between cost efficiency and quality is often challenging. Engaging experienced professionals for advisory roles may help navigate this complex landscape.